Page 273 - Pressure Swing Adsorption

P. 273

l interstitial gas 1s transferred through the feed end to the A bed (counter-

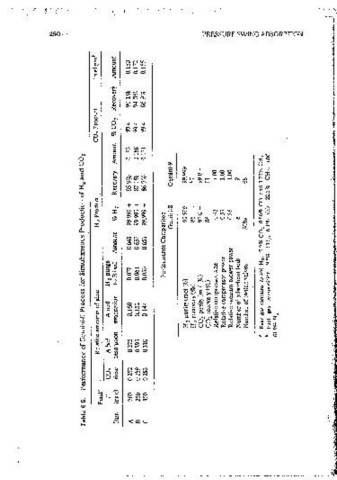

250 PRESSURE SWING ADSORPTION ' PSA PROCESSES 251

current), thus rectucmg the pressure from PH to Pi-

J 83. Countercurrent Deoressunzation II. The bed is connected to another B

bed, which 1s undergoing step 86 and more of the desorbate and

mterstitial gas 1s removed (countercurrently) through the feed end,

reducing the pressure to P •

2

B4. Countercurrent Deoressurizat10n III. The bed is blown down from P to

2

atmosohenc pressure, and the effluent gas, which contains a orooort1on

of the feed imourities together with some hydrogen, 1s reJectect.

B5. Countercurrent Purge. The bed is ourged at atmospheric oressure with

high-purity hydrogen product to desorb any impurities further. The

effluent is rejected.

B6. Cocurrent Pressunzat1on. The pressure m the bed is raised to P 2 by

+ 888 connecting with another B bed undergomg step BS.

I o-t-0, ..................... 0,00 B7. Countercurrent Pressurizat10n. Final pressurization of the B bed to PH

0

0-000-0\

10

is accomplished with hydrogen product, mtroduced from the product

end. During the later part of this step the B bed is connected with

+ + + another A bed undergoing step A6 and both beds are then pressurized

g::gg to PH.

"' 0- 0-

g: ~ g:

The B beds pass through two complete cycies (steps Bl to B7) while the A

beds go through one cycle so that each B bed handles the gas from two A

beds during the complete cycle. This approach reduces significantly the size

of the B beds. A key feature of this cycle 1s that =the A and B beds are

connected m senes dunng the adsorption step but thev are regenerated by

00 - 0

!'-- IO in two entirely different sequences. The overall performance 1s sumrnanzect m

00 0

00 0

Table 6.5. It 1s evident that the hydrogen product has a puntv greater than

99.999% and the fractional recovery 1s about 86-87%, while the CO prod-

2

uct is produced at a purity of about 99.4% with about 90% recovery. The

Gemini-8 process gives slightly lower ounty and recovery of CO , but there is

2

a significant reduction in the size of the compressors and the oower con-

sumption.

6.10 PSA Process for Concentrating a Trace Component

In the processes described so far in this chapter the objective has generally

been to produce a oure raffinate product, although in some cases the more

strongly adsorbed species (the extract product) 1s also recovered m concen-

trated form. However, particularly m environmental applications, it is often

necessary to concentrate a trace component for disoosal or further process-

ing_._ Provided that a sufficiently selective adsorbent 1s available, PSA appears

to be well smtect to such applications, although to date few, if any, processes

of this kind have been commercialized. Examoles of :two such processes that

have been developed to the pilot plant scale are described m this section.