Page 270 - Pressure Swing Adsorption

P. 270

I

246 PRESSURE SWING ADSORPTION PSA PROCESSES 247

(CO- • N , 0 ) diffuse mto the adsorbent much faster than methane. which 1s

2 2 2

therefore produced as the raflinate product. A high recovery (over 90%) IS

reported, with the product contammg 87-89% methane with the balance .. .. <i:

a:

CO + N • a: UJ CL

"'

2

2

w

a:

a: 0

a,

w u a: w 0 a, w, 0

w

J ~ Q. U> w w, CL. ' UJ

;l

z

w

w

CL a,

6.8 Hydrocarbon Separations E w <( w 0 0: u. .,,, a, u.

.. l 11/~

,.,

<l--2 .. ._ l

The separation of linear from branched and cyclic hydrocarbons using 5A a: ..

a:

a:

zeolite as the adsorbent is one of the earliest examples of a moiecular sieve .. Q. UJ

UJ

separation process. In the low-molecu1ar-we1ght range (up to C 10 ) a pressure w u a: w .......£... ,___«:_

a:

w

swing version of the "Isos1v" process is commonly used. The system, which 1s '-- ~ Q. "' 0 w "'"' 0 w w a,

z

w

o. I

o. I

w

J

w

.,,,

w 0 0: u. e a, u. a,

m essence a standard pressure /vacuum swing system, 1s shown schematically w <( ~ ~

o. I

m Figure 6.19. High-purity linear paraffins are produced as the desorbate a, w <( ~.,,(/' ..

o. I

a,

ctunng the evacuation step, while durmg the adsorotion steo a raffinate .. a:

a:

a: Q.

stream deoieted of normals 1s produced. The operating temperature and Q. w w

w a: 0

oressures depend on the molecular weight range, but for the C feedstock, u a: w 0 w a: 0 w w"'

6

w

U>

Q.

350° C with a pressure swmg from 20 to 0.2 atm 1s typical. 27 A somewhat ;l w z u. J e ~ w D.: l w '\'

w

.. a,

u.

w

0

0:

similar process has been developed by B.P. 32 "' <( .,,, w <

o. I

.,

a, .s-,, .. .. 1

Q. ..

a: a:

6.9 Process for Simultaneous Production of H and CO from a: w w

2 2 Q. a: 0

w

Reformer Off-Gas a: "' 0 a: u w., 0

.,

Q. Ul "' '-- UJ"' .. ! w

J

o. l

w z "' w e ~ a, w

0 0: u. w < "' .,,, u.

The crude hydrogen stream 'from a steam reformer contains significant o. I UJ <(

,rnantities of carbon dioxide, which, by appropriate design of the seoarallon a, <l--2 .. .. '

a,

.. ..

a:

a:

a: w

Q. UJ

CRUDE H, w u a: .........e.... ~

a:

a,

0

FEED "' 0 "' ~ Q. ~ 'f w ....

Ul

UJ i

;l

UJ

z

J

. COMP 0: "' w e w "' ~

u.

0

u.

..,,,

w <( ~

o. I w<

a, .. J, <l--2 ..

=..--·· .,__Ptl'\!O"'QUCT CO,

..

t

a: " !l:

Q.

w

w

w a: 0

..

p 0 w a: 0 a: w 0 w., w ..

w J '---- Ul w

w

w e ll w z u. .. ' .. ~

u. w 0 0: a,

w <( ..,,,

.. J, w <(

<l--2 .. o. I

a,

N N

<( a,

S038V S038 B

/a)

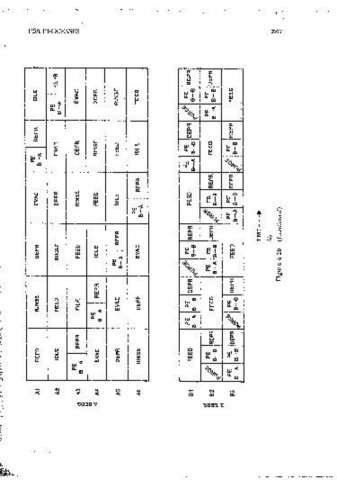

Figqr~ 6.20 (a) Simplified process flow sheet. (b) flow schedule for the Gernini-9

prcfcess for simultaneous production of H 2 and CO 2 from reformer gases. (From

Sircar 17 and Kumar et al., 34 with pern11ss10n.)