Page 266 - Pressure Swing Adsorption

P. 266

242 PRESSURE SWING ADSORPTION PSA PROCESSES

243

Table 6.3. Composition of Typical Coke Oven Gas

"'OSie gos

Concentration

Components (% by vol.)

H, 59.99

adsorption pressure

CH, 22.76 i.i - 1.J bar

N, 6.68 co,

co 5.45

C 2 H,1 1.66 feed

o, J.40 gas

co, 1.26

C 2 H{, 0.53 blower

c_,H,, 0.11

C2H2 0.09

0.02

C 1 H 8

final desorption

C 4 H1, 0.02 pressure:

C<iHo 0.02 approx. 50 mbor

C4Ho 0.01

C 4 H 10 0.01

CsH12 0.01 vacuum

pump

Ct,H14 0.01 product gos

C 7 Hu, 0.01

C7Hs 0.01 co,

(>997. by vol.)

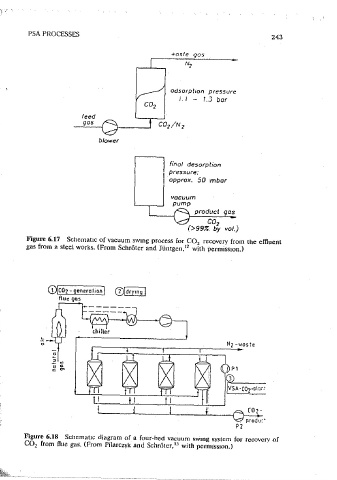

Source:' Ref. 30. Figure 6.17 Schematic of vacuum swmg process for CO recovery from the effluent

2

gas from a steel works. (From Schr5ter and Jiimgen, with permission.)

12

6.5!3 Bergbau - Forschung Process

As an alternative to the zeolite-based hydrogen recovery orocesses developed

by Union Carbide, Bergbau-Forschung has developed eau1vaient processes (i)!co2-9enerationl (D~

using a wide~oore carbon molecular sieve as the adsorbent. A four-bed

flue gas

system is used with five snialler preadsorption beds contaming activated

carbon and Ooerat10g between atm and 1 atm. The process seQuence, which

is basically similar to that used m the four-bed Union Carbide system. is

shown m Figure 6.16. This system has been used orimarily to recover

hydrogen from coke oven gas containing about 60% hydrogen (see Table 6.3).

Hydrogen oroduct purittes as high as 99.999% at a recovery of 85% are

3

claimed, and the largest units have a product rate of 10 4 N m /h. The

oerformance thus appears to be broadly similar to that of the Union Carbide

poiybed system, b1Jt smce only four beds are used, there should be a cap1tai

cost advantage.

6.6 Recovery of CO

2 ~---'~--'~---'i'----~

\dp~~W·

PZ

Carbon dioxide 1s present at relatively high concentrations (15-35%) in the

flue gases from many mdustnes such as steel and lime oroctuction. Since CO 2 Figure 6.18 Scilemat1c diagram of a four~hed vacuum i;Wmg system for recoverv of

ts strongly adsorbed on many adsorbents, mcluding both zeolites and carbon CO2 from flue gas. (From Pilarczyk and Schrt'iter, u with permission.) -