Page 262 - Pressure Swing Adsorption

P. 262

238 PRESSURE SWING ADSORPTION PSA PROCESSES 239

signed to orovide local sources of high-ourity hydrogen. 18 23 Large-scale

-

These processes, which employ up to twelve beds with several pressure I Pressuri-

mult1ole-bed processes were cteveioped m the late 1970s, the first bemg the

24

41 MMSCFD plant at the Wintershall AG Lingen refinery m Germany.

rnlloJl

equalization steps, can achieve hydrogen recovenes in the 8S-90% range at l Lrne

99.99% nurity from a typical feed containing 75% l--1 • 25 28 '

-

2

Pre\11.1re

Eq1.1i!1za!\Oll

Lifle

6.5.1 The Four-Bed Process

The system for the ·four-bed orocess 1s essentially similar to the four-bed

oxygen process (Lindox) shown m Figures 3.9 and 3.10. A mixed adsorbent of

Ad~orp!ion

activated carbon and 5A zeolite is commonly used, although, smce the Bod

selectivity for most impurities relative to hydrogen is high, almost any

adsorbent can be employed. Production of a hydrogen product with 99.99%

purity at 'JS% recovery from a feed contaming 70-80% hydrogen is claimed

for the four-bed process with two pressure equalization steps. The process

Feed

~JPerates between 20-30 atmospheres and 1-2 ·atmospheres. The cycle is

(al

F 2 3 4 5 6 7 8 9 10 11 12 13 mm 20 sec.

30.B "

-

I 10.0 Time (minutes)

f (b)

I

.s I TIME UNIT

I s i 6 I 7 i a I 9 I 10 I 11 112 I 13 I 14 l 15 I 16 I 17 I 18 1

f • no loo "' i " " I ' j E)R 011 I [111 " I

1.0

' 2 • 80 j '

' (IR ! FR , I EIO l E20 I ElO " ' I DR (2JI I

I

I 3 ElRIE2R EIR ! FR • '" E20 I ElO '' " I ' '

i

I ffi ' E)R I E?R '" " • i EID no j EJO " so I

m 4

0.1 ~ a: pp I so ' "' "' [IR I ri:1 • IE10 no j no " I

g 5

' 0 0 2 6 ""I " I " ' EJR I E211 ElR I FR • I [10 £20 i

' I ' 0 7 [1D i £20 w ElR !011 • I

I "'I "' ' '" " I

I 8 • w • I

0.001 £!0 I E20 j EJO I " ' n11j0Rjrn1 " I I

9 • i E!O oo jno I " ! " ' ' ! ElR ; £,R ! E!R : l"f:I ' •

70 80 90 100 '

2 3 4 5 6 7 8 9 10 11 12

Hydrogen Recovery (..-011, l Time (minutes)

Figure 6,13 Experimental recoverv-punty profile for four-bed H 2 PSA system. (cl

(From Tomita et al., 23 with oermisston.)

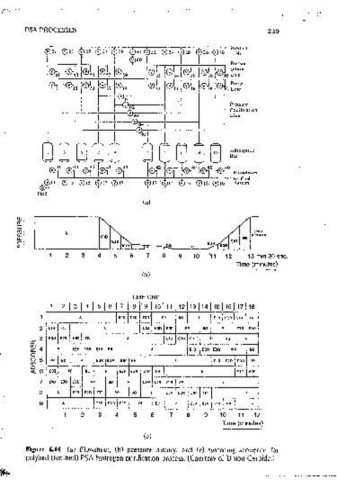

Figure 6.14 (a) Flowsheet, (b) pressure histol)', and (c} switching seouence for

polvbed (ten-bed) PSA hydrogen purification process. (Courtesv of Umon Carbide.)