Page 263 - Pressure Swing Adsorption

P. 263

240 PRESSURE SWING ADSORPTION R•acior A Adr.orplion ::,~::: - !Cl,,!.':~"'' - P11r911 ,.,,.,.

c , •• ,. - ) .. .,.,.. .. ..,.,-

c.,,,.,._ /0.,.,0 ..... ,- ,.1,_

R•11ctor B ,,,_ ,.,_ P1.1rg11 ~:;::~ - I"'~:.' .. "" - Ad•otpt,on

shown m Figure 6.12. Details concernmg the optimization have been given by R1usctor C Purr,• f:~ - 1"'-r.::: .. "'•· Adr.orpfJ011 !::-.:~ - 1-:;;:::·

Doshi et al. 22 Results of an expenmental pilot scale study of the four-bed R,vctor D - ::~=~·- /"•::.;:::-·· Adr.orplion !::::~· - 10·::::: .. '""•· , P11rge

23

hydrogen PSA process have been reported by Tomita et al. Some of thetr

/a)

results are presented m Table 6.2 and Figure 6.13.

A d.etailed theoret1cal opt1m1zat1on of the design of a zeolite-based hydro-

gen PSA unit~ for feed and oroduct specifications typical of industrial

practice. has been earned out by Smith and Westerberg. 30 Their results ZI

illustrate clearly the economy obtained from an optimal choice of operatmg

pressures and the number of equalization steps. For smaller-scale plants a

smgie eaualization step 1s preferable, but as the throughput mcreases the

ootimum shifts towards two or three equalization steos as a result of the

proportionately greater importance of operating versus caoital costs (see 8

Figure 1.3). The oot1mal operatmg pressure, for a system with two eoualiza- I

tions, is about 18 atm. These conclus1ons are in line with current 1ndustnal

F3J

practice.

C

6.5.2 Polybed Process

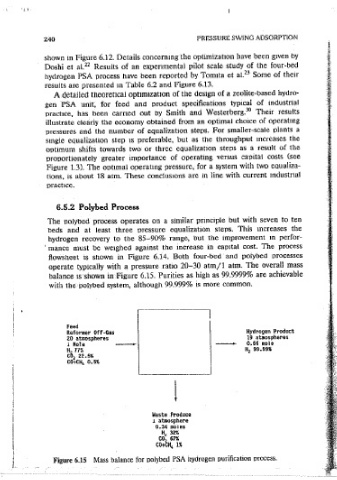

The oolybed process operates on a similar prmciple but with seven to ten

beds and at least three pressure equalization steps. This mcreases the

hydrogen recovery to the 85-90% range, but the improvement m perfor- D

' mance must be weighed against the increase in capital cost. The process I

flowsheet 1s shown in Figure 6.14. Both four-bed and polybed processes

operate typically with a pressure ratio 20-30 atm/1 aim. The overall mass '------''.l::::'.... ____ ..'.f'.:'::'."''_ __ -~·i~·----' ----~''r ... ,

Joo....

, ,

balance 1s shown m Figure 6.15. Purities as high as 99.9999% are achievable

(b)

with the polybed system, although 99.999% 1s more common.

Feed

Reformer Off-Gas Hydrogen Product

20 at1110spheres 19 atmospheres

.i Hole 0.66 mole

H 77% H 99.99t

2

co, 22.5%

CO+CH 4 0.5%

l

Waste Produce

.1 atmosphere

o.34 moles (c)

H 32%

2

co 67%

CO+~H, 1% Figure 6.-16 Switching seauence, pressure history, and schematic flowsheet for four-

bed carbon molecular sieve hydrogen purification process. (From Pilarczvk and

13

Knoblauch, with oenmss10n.)

Figure 6.15 Mass balance for oolybed PSA hydrogen purification orocess.