Page 258 - Pressure Swing Adsorption

P. 258

-~ _,.......,,, 1,--.· -·

(

i

234 PRESSURE SWING ADSORPTION PSA PROCESSES 235

16 17

100.0 ,-------==------------~ vacuum swing adsorotion process (VSA), · which :JS described here. An-

other similar cycie ts discussed m Sechons 4.4.5 ,and 4.5. The orocess

PURITV=81•85%

t P,. = 800 TORR operates with what is basically a two-bed system, but each "bed" actually

T = 19.0"C

0

t 99,0 - P = 50 TORR consists of a orebed for 1mounty removal m senes with the mam adsorption

5 ~ bed. The sequence of ooerat1ons, which involves five distmct steos, 1s shown

"' .. schematically m Figure 6.!0(b). The followmg ctescnpt1on 1s taken from

0

17

a;: H.oi- \ Sircar.

Feed/ 0 2 Product. Air at near-ambient pressure is passed through the orebed

and main bed, which have been orev1ously raised to ambient pressure in

97.0 ~---~ '---~·---~ '--~---~ steps (d) and (e) of the cycle. H 0 and CO are removed m the orebed,

0.10 0.15 0.20 0.25 0.30 0.35 2 2

and the dry CO free a!f then oasses to the mam bed, where N IS

N 2 PAOOUCTION CAPACITY, MIWPOUNO MOLES/LB - 2 2

(a) selectively ctesorbed to yield the oxygen-rich product stream. some of

which ts stored m a gas tank for use as the pressurization gas m step (c).

100 ,--------------------,

This step 1s terminated at or before the breakthrough of N •

2

2

t .. Nz PURITY» 99,!l'lio N 2 Rinse. A stream of the N -nch product is passed through both the prcbed

I T"' HI.O"C and the main bed in the cocurrent direction. The effluent is a dry CO 2

~ PA .. eoo TORR free gas with a composition close to that of air. A part of' this gas ts

0

~ •o • 50-55 TORR

Q therefore recycled as feed alr to reduce the load oh the prebed. This step

0

• • •• IS continued until both the orebed and main bed are essentially saturated

~

"' •• with nitrogen .

N

0

,,_ Vacuum Desomtwn. Both adsorbers are now evacuated from the 0 oroduct

2

enct (countercurrent direction), producing the nitrogen-enriched oroduct

stream. This stream, however, contams essentially: all the CO and H 0

1 2 2

t•,-,---,,-_ ... ,,----,-.,'-,---."'.,-,---,,-'_,,-,----o. 10

desorbect from the prebed. A fraction of this gas JS stored for use as the

02 PRODUCTION CAPACITY, a.lllLLIPOUND MOLl!!S/LB -

(b) nitrogen rinse (step b) m the other pair of beds, while the remainder is

withdrawn as the Ni-rich product. Evacuation JS continued in this manner

% 02 IN PRODUCT -- until the pressure reaches a preset value at which· the valve between the

prebed and the rnam bed 1s closed.

1n70 80 90 100 Evacuation/ 0 Pressurization. Evacuation of the prebed 1s continued with

~ the ctesorbate bemg added to the mtrogen-nch product. Meanwhile the

2

t 60 main bed is pressurized with part of the oxygen,rich product from the

,. storage tank.

I

"' ~\ Air Pressurization. Finally the interconnecting valve between the pre and

"'

• •

>

0 main beds 1s opened, and the orebed is brought up to feed pressure with

0 50

"' oxygen from the storage tank through the mam bed, thus completing the

"' ,,_

cycle. The performance 1s shown m Figure 6.11. (See also Figures 4.14 and

•o----------- 4.15.)

97

99

100

98

% N7 IN PRODUCT -

6.5 Hydrogen Recovery

(c)

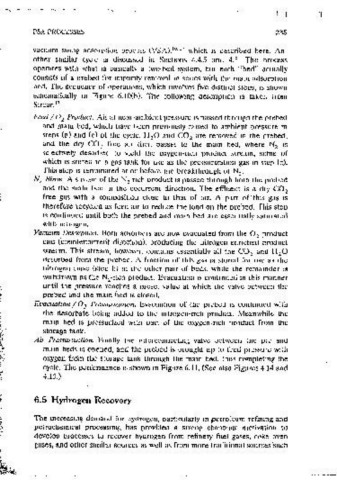

Figure 6.11 Perforlllance of Air Products Vacuum swing air separation process. The mcreasing demand for hydrogen, particuiarly in ,petroieum refining and

Adsorbent, Na mordenite; feed pressure. LOS atmi desorption pressure (mam bed), petrochem1cal processing, has provided a strong· economic motivation to

50-55 Torr; prebect; 25-30 Torr. (a) Nitrogen oroduct purity; (b) oxygen product

punty as a funct10n of product rate; and (c) recovery-purity profile for both products. deveioo orocesses to recover hydrogen from refinery fuel gases, coke oven

(From Sircar 17 with oerm1ssion.) gases, and other similar sources as well as from more traditional sources such