Page 259 - Pressure Swing Adsorption

P. 259

236 PRESSURE SWING ADSORPTION PSA PROCESSES 237

I as reformer off gas. For most applications a high-pur:ity hydrogen product is

reamred (at least 99.99% and often 99.999%). Since hydrogen 1s adsorbed

much less strongly than almost any other species, a well-designed pressure

S1cp i swmg system can meet this challenge. Indeed this 1s one application for

~

• A B C D which PSA has a clear advantage over almost all other possible approaches,

'

a

C < for many of which these punty levels are unattamable.

0" A-I C I

u .":'.

_, , Commercial 1mpiementation of PSA processes for hydrogen recovery

E

0 C

u

~" 0 I dates from the late 1960s, but the earlier processes were small-scaie three- or

u,

C,

·" T Feed t Vac. .E four-bed umts with relatively modest perfonnance ( ~ 70% recovery) de-

"-

2-3 C

C

,

·2 "E.

08 Adsorbem SA zeolite

• ~ Table 6.2. Details of Test Conditions and Performance Data for a ·Four-Bed Hydrogen

<

0 C ~ PSA Purification System

A-2 A D

Size

i-4 mm (4-18 mesh)

Form spherical beads

I Vac. 1 Blow

Bulk density 0.74kg/l

Feed cone.

H, 69.2vol%

N, 26.8

co 2.2

" CH, 1.8

A C D

Pressure

Adsorption Pa 8.6 kg/cm 2

Vac. Purge PP I.5 kg/cm 2

First equilibration P 1 5.2 kg/cm 2

Second equilibration P,, 1.9 kg/cm 2

Al A2 Bl B2 Cl C2 DI D2

Run no. 2 3 4 5 6 7 8 9 IO 11

J

i

] . i Feed rate (Nljmin)a 14.9 14.6 14.6 21.0 20.9 20.9 8.3 8.3 14.6 14.6 14.5

6.0

8.0

Cyde Time {min)

12.0

48.0

24.0

47

,

~ 2 ---t-------r-- Column size 4.3 cm 1.d. x 200 cm L. 8.4 16.8 33.6 21.0 42.0 4.3 cm 1.d. x 100 cm L.

.!::<

Adsorbent (kg) 2.06 X 4 bed 1.0 x 4bed

• C

~ E Product cone.

iP ' ' H (vol%) 99.73 85.61 76.19 99.38 84.22 76.55, 99.93 83.48 99.87 97.93 88.41

" C

'

~v ' N, 2 0.27 13.41 21.15 0.62 14.52 20.86 0.07 15.19 0.13 2.06 10.9

'

' I ' I co 0.0 0.52 1.48 0.0 0.68 t.45 0.0 0.68 0.0 0.0 0.39

!

___ .J _______ J.._Q_ I ala

0.0 0.47 1.18 0.0 0.58 1.14 0.0 0.65 0.0 O.Ql 0.30

0 2 4 CH 4

H Recovery(%) 77.7 88.4 94.9 77.2 90.3 94.6 77.7 90.5 70.0 78.6 83.9

Time (mm.) 2

Adsorbent

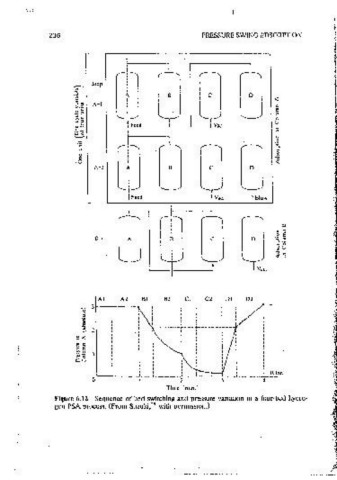

Figure 6.12 Sequence of bed switching and pressure variation in a four-bed hydro- productivitv 21.7 42.7 84.9 21.4 42.6 85.2 21.3 42.5 17.0 21.8 29.0

gen PSA process. (From Suzuki, 29 with permission.) Q (NI/kg ads.,

cvcle)

Space veiocilV

0/mm) 0.66 0.63 0.62 0.90 0.87 0.84 0.37 0.37 1.30 1.29 i.26

NI = liters at 273 K I atm.

23

From Tomita et al., with perm1ss1on.