Page 141 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 141

138 Chapter 5 Heat exchanger network analysis

(A) (B)

HP

HP

steam steam

Hot

composite

curve

LP

T T steam

Hot Cold composite

Cold composite ΔT min curve

composite curve ΔT min

curve

CW CW

H H

(C) (D)

HP HP

steam steam

*

T LP LP steam Utility pinch

Grand composite

curve Grand composite

T * T * curve

Process pinch

*

T cw Utility pinch

Refrigeration CW

Refrigeration

Δ H * Δ H *

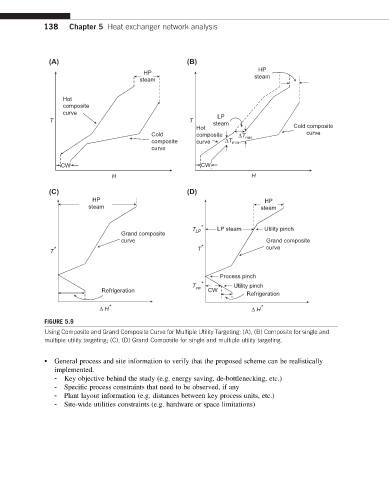

FIGURE 5.9

Using Composite and Grand Composite Curve for Multiple Utility Targeting: (A), (B) Composite for single and

multiple utility targeting; (C), (D) Grand Composite for single and multiple utility targeting.

• General process and site information to verify that the proposed scheme can be realistically

implemented.

- Key objective behind the study (e.g. energy saving, de-bottlenecking, etc.)

- Specific process constraints that need to be observed, if any

- Plant layout information (e.g. distances between key process units, etc.)

- Site-wide utilities constraints (e.g. hardware or space limitations)