Page 16 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 16

10 Chapter 1 General aspects of process design

Fuel Gas

Amine Treating Refinery Fuel

H S

Other Gases 2 Claus Sulfur Sulfur

Plant

LPG

Gas Gas Processing Merox Treaters H S from

2

Sour Water Stripper

Gas H 2 Gas H 2

Light Isomerization Isomerate

Hydrotreater

Naphtha Plant

Gas H Gas H 2

2

Heavy Hydrotreater Reformer Reformate

Catalytic

Atmospheric Distillation Merox Treater Kerosene

Naphtha

Crude Kerosene Gas H 2

Oil Gas H 2 Hydrocracker Gasoline

Diesel Oil

Hydrotreater Diesel Oil Hydrocracker Diesel Oil Gas Gasoline Blending Pool

Atmospheric i-Butane

Alkylate

Gas Oil Butenes Alkylation

Heavy Vacuum

Pentenes

Gas Oil Gas Gas H 2

Evacuated

non-condensibles Gas H 2 Naphtha Hydrotreater FCC Gasoline

Atmospheric Bottoms Light Hydrotreater Fluid Catalytic Cracker (FCC) FCC Gas oil

FCC Feed

Vacuum

Gas Oil Fuel oil

Vacuum Distillation Vacuum

Heavy

Gas Oil

Asphalt

Air Blowing Asphalt

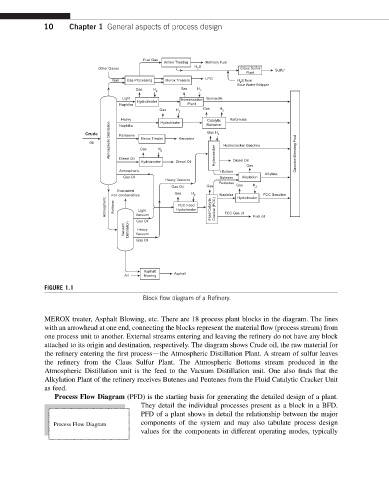

FIGURE 1.1

Block flow diagram of a Refinery.

MEROX treater, Asphalt Blowing, etc. There are 18 process plant blocks in the diagram. The lines

with an arrowhead at one end, connecting the blocks represent the material flow (process stream) from

one process unit to another. External streams entering and leaving the refinery do not have any block

attached to its origin and destination, respectively. The diagram shows Crude oil, the raw material for

the refinery entering the first processdthe Atmospheric Distillation Plant. A stream of sulfur leaves

the refinery from the Claus Sulfur Plant. The Atmospheric Bottoms stream produced in the

Atmospheric Distillation unit is the feed to the Vacuum Distillation unit. One also finds that the

Alkylation Plant of the refinery receives Butenes and Pentenes from the Fluid Catalytic Cracker Unit

as feed.

Process Flow Diagram (PFD) is the starting basis for generating the detailed design of a plant.

They detail the individual processes present as a block in a BFD.

PFD of a plant shows in detail the relationship between the major

Process Flow Diagram components of the system and may also tabulate process design

values for the components in different operating modes, typically