Page 20 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 20

14 Chapter 1 General aspects of process design

Ø298 202 34

Ø345

3

25

Ø6mmX185 nos

DETAIL-D

36

3 43

DEAIL-C

M24X3 15.4

15

DETAIL-B

15 3 122

N31 45.6 158.5 3

134.5 3

DETAIL-A 75

73.2 134.5 DETAIL-C N32 8

DETAIL-D M24X3 DETAIL-A

28.3 28.3

DETAIL-B

NOTE :

1. N31 & N32-- 1/2**NB, SCH40 NOZZLE with 1/2*NB Flange as per*ASA Class 150/B16.5/BS 1560

2. All bolts are M24X3, 50 mm Lg. as per ANSI B18.2.3.5M-1979

3. All Nuts are M24X3 as per ANSI B18.2.4.1M & M24 regular washer asper ANSIB 18.22M-1981

4. M.O.C. of all equipments, Vessles, Flanges, Pipes, Nozzles, Nut & Bolts IsSS304

DRAIN POT

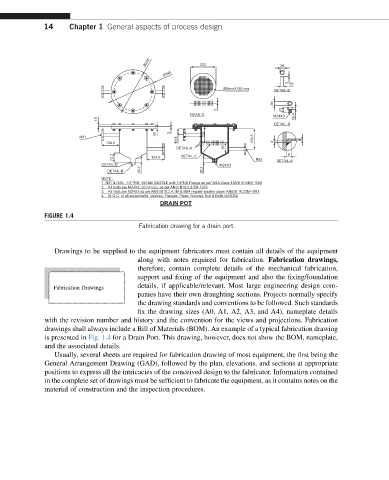

FIGURE 1.4

Fabrication drawing for a drain port.

Drawings to be supplied to the equipment fabricators must contain all details of the equipment

along with notes required for fabrication. Fabrication drawings,

therefore, contain complete details of the mechanical fabrication,

support and fixing of the equipment and also the fixing/foundation

Fabrication Drawings details, if applicable/relevant. Most large engineering design com-

panies have their own draughting sections. Projects normally specify

the drawing standards and conventions to be followed. Such standards

fix the drawing sizes (A0, A1, A2, A3, and A4), nameplate details

with the revision number and history and the convention for the views and projections. Fabrication

drawings shall always include a Bill of Materials (BOM). An example of a typical fabrication drawing

is presented in Fig. 1.4 for a Drain Port. This drawing, however, does not show the BOM, nameplate,

and the associated details.

Usually, several sheets are required for fabrication drawing of most equipment, the first being the

General Arrangement Drawing (GAD), followed by the plan, elevations, and sections at appropriate

positions to express all the intricacies of the conceived design to the fabricator. Information contained

in the complete set of drawings must be sufficient to fabricate the equipment, as it contains notes on the

material of construction and the inspection procedures.