Page 174 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 174

172 Chapter 6 Evaporators

shorter residence time as compared to rising film evaporators for any given set of conditions. The

temperature is also more uniform in falling film types as there is no problem of hydrostatic head, and the

only critical concern is the feed distribution system.

Due to the combined feature of functioning at the low-temperature difference and short residence

time, the falling film evaporator is highly suitable for temperature-sensitive products. Typical appli-

cations include the concentration of dairy products, sugar solutions, urea, phosphoric acid, and black

liquor.

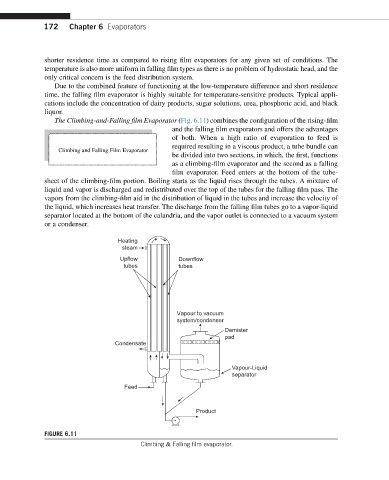

The Climbing-and-Falling film Evaporator (Fig. 6.11) combines the configuration of the rising-film

and the falling film evaporators and offers the advantages

of both. When a high ratio of evaporation to feed is

required resulting in a viscous product, a tube bundle can

Climbing and Falling Film Evaporator

be divided into two sections, in which, the first, functions

as a climbing-film evaporator and the second as a falling

film evaporator. Feed enters at the bottom of the tube-

sheet of the climbing-film portion. Boiling starts as the liquid rises through the tubes. A mixture of

liquid and vapor is discharged and redistributed over the top of the tubes for the falling film pass. The

vapors from the climbing-film aid in the distribution of liquid in the tubes and increase the velocity of

the liquid, which increases heat transfer. The discharge from the falling film tubes go to a vapor-liquid

separator located at the bottom of the calandria, and the vapor outlet is connected to a vacuum system

or a condenser.

Heating

steam

Upflow Downflow

tubes tubes

Vapour to vacuum

system/condenser

Demister

pad

Condensate

Vapour-Liquid

separator

Feed

Product

FIGURE 6.11

Climbing & Falling film evaporator.