Page 170 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 170

168 Chapter 6 Evaporators

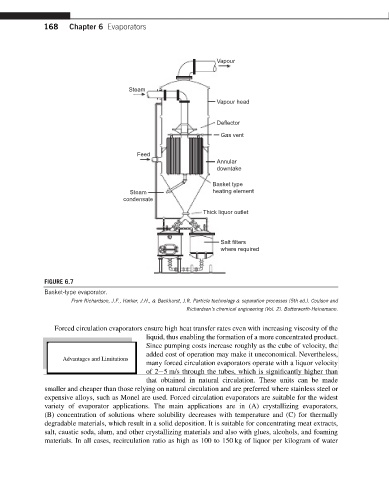

Vapour

Steam

Vapour head

Deflector

Gas vent

Feed

Annular

downtake

Basket type

Steam heating element

condensate

Thick liquor outlet

Salt filters

where required

FIGURE 6.7

Basket-type evaporator.

From Richardson, J.F., Harker, J.H., & Backhurst, J.R. Particle technology & separation processes (5th ed.). Coulson and

Richardson’s chemical engineering (Vol. 2). Butterworth-Heinemann.

Forced circulation evaporators ensure high heat transfer rates even with increasing viscosity of the

liquid, thus enabling the formation of a more concentrated product.

Since pumping costs increase roughly as the cube of velocity, the

added cost of operation may make it uneconomical. Nevertheless,

Advantages and Limitations

many forced circulation evaporators operate with a liquor velocity

of 2e5 m/s through the tubes, which is significantly higher than

that obtained in natural circulation. These units can be made

smaller and cheaper than those relying on natural circulation and are preferred where stainless steel or

expensive alloys, such as Monel are used. Forced circulation evaporators are suitable for the widest

variety of evaporator applications. The main applications are in (A) crystallizing evaporators,

(B) concentration of solutions where solubility decreases with temperature and (C) for thermally

degradable materials, which result in a solid deposition. It is suitable for concentrating meat extracts,

salt, caustic soda, alum, and other crystallizing materials and also with glues, alcohols, and foaming

materials. In all cases, recirculation ratio as high as 100 to 150 kg of liquor per kilogram of water