Page 171 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 171

6.3 Evaporator types 169

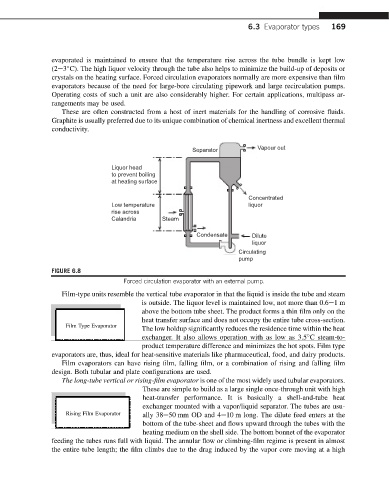

evaporated is maintained to ensure that the temperature rise across the tube bundle is kept low

(2e3 C). The high liquor velocity through the tube also helps to minimize the build-up of deposits or

crystals on the heating surface. Forced circulation evaporators normally are more expensive than film

evaporators because of the need for large-bore circulating pipework and large recirculation pumps.

Operating costs of such a unit are also considerably higher. For certain applications, multipass ar-

rangements may be used.

These are often constructed from a host of inert materials for the handling of corrosive fluids.

Graphite is usually preferred due to its unique combination of chemical inertness and excellent thermal

conductivity.

Vapour out

Separator

Liquor head

to prevent boiling

at heating surface

Concentrated

Low temperature liquor

rise across

Calandria Steam

Condensate Dilute

liquor

Circulating

pump

FIGURE 6.8

Forced circulation evaporator with an external pump.

Film-type units resemble the vertical tube evaporator in that the liquid is inside the tube and steam

is outside. The liquor level is maintained low, not more than 0.6e1m

above the bottom tube sheet. The product forms a thin film only on the

heat transfer surface and does not occupy the entire tube cross-section.

Film Type Evaporator

The low holdup significantly reduces the residence time within the heat

exchanger. It also allows operation with as low as 3.5 C steam-to-

product temperature difference and minimizes the hot spots. Film type

evaporators are, thus, ideal for heat-sensitive materials like pharmaceutical, food, and dairy products.

Film evaporators can have rising film, falling film, or a combination of rising and falling film

design. Both tubular and plate configurations are used.

The long-tube vertical or rising-film evaporator is one of the most widely used tubular evaporators.

These are simple to build as a large single once-through unit with high

heat-transfer performance. It is basically a shell-and-tube heat

exchanger mounted with a vapor/liquid separator. The tubes are usu-

Rising Film Evaporator ally 38e50 mm OD and 4e10 m long. The dilute feed enters at the

bottom of the tube-sheet and flows upward through the tubes with the

heating medium on the shell side. The bottom bonnet of the evaporator

feeding the tubes runs full with liquid. The annular flow or climbing-film regime is present in almost

the entire tube length; the film climbs due to the drag induced by the vapor core moving at a high