Page 167 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 167

6.3 Evaporator types 165

Heating may be either direct or indirect. Direct heating is provided by solar evaporation (pro-

duction of Glauber’s salt) and submerged combustion of a fuel. The advantages of this technique are

the ability to handle corrosive liquors, a large amount of heat release per unit volume (typically

3

70 MW/m ) in submerged combustion and the almost instantaneous transmission of heat to the liquid.

Generally, the most widely used mode of indirect heating is by condensing steam or vapor on the heat

transfer surface.

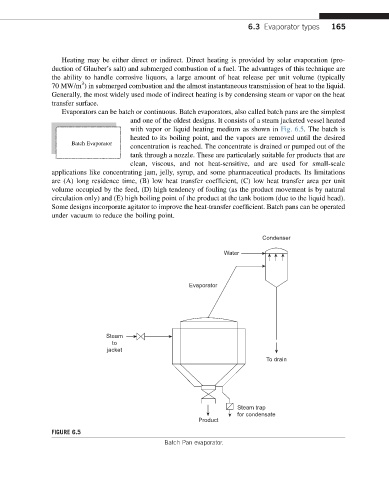

Evaporators can be batch or continuous. Batch evaporators, also called batch pans are the simplest

and one of the oldest designs. It consists of a steam jacketed vessel heated

with vapor or liquid heating medium as shown in Fig. 6.5. The batch is

heated to its boiling point, and the vapors are removed until the desired

Batch Evaporator

concentration is reached. The concentrate is drained or pumped out of the

tank through a nozzle. These are particularly suitable for products that are

clean, viscous, and not heat-sensitive, and are used for small-scale

applications like concentrating jam, jelly, syrup, and some pharmaceutical products. Its limitations

are (A) long residence time, (B) low heat transfer coefficient, (C) low heat transfer area per unit

volume occupied by the feed, (D) high tendency of fouling (as the product movement is by natural

circulation only) and (E) high boiling point of the product at the tank bottom (due to the liquid head).

Some designs incorporate agitator to improve the heat-transfer coefficient. Batch pans can be operated

under vacuum to reduce the boiling point.

Condenser

Water

Evaporator

Steam

to

jacket

To drain

Steam trap

for condensate

Product

FIGURE 6.5

Batch Pan evaporator.