Page 168 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 168

166 Chapter 6 Evaporators

6.3.1 Types of continuous evaporators

Continuous evaporators are further classified based on (i) the method of agitation or the nature of liquid

circulation over the heating surface, (ii) movement of the evaporating film, (iii) type of heat transfer

surface.

Evaporators may be divided into three main types on the basis of nature of circulation:

(a) Natural circulation units

(b) Forced circulation units

(c) Film-type units

In natural-circulation evaporators, the circulation of the liquid is effected by employing a short

length of the tube. These evaporators are further classified as horizontal tube and vertical tube type.

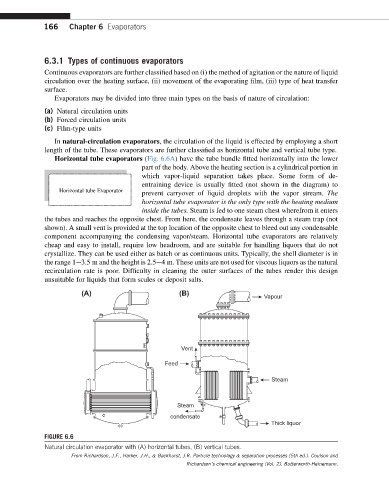

Horizontal tube evaporators (Fig. 6.6A) have the tube bundle fitted horizontally into the lower

part of the body. Above the heating section is a cylindrical portion in

which vapor-liquid separation takes place. Some form of de-

entraining device is usually fitted (not shown in the diagram) to

Horizontal tube Evaporator

prevent carryover of liquid droplets with the vapor stream. The

horizontal tube evaporator is the only type with the heating medium

inside the tubes. Steam is fed to one steam chest wherefrom it enters

the tubes and reaches the opposite chest. From here, the condensate leaves through a steam trap (not

shown). A small vent is provided at the top location of the opposite chest to bleed out any condensable

component accompanying the condensing vapor/steam. Horizontal tube evaporators are relatively

cheap and easy to install, require low headroom, and are suitable for handling liquors that do not

crystallize. They can be used either as batch or as continuous units. Typically, the shell diameter is in

the range 1e3.5 m and the height is 2.5e4 m. These units are not used for viscous liquors as the natural

recirculation rate is poor. Difficulty in cleaning the outer surfaces of the tubes render this design

unsuitable for liquids that form scales or deposit salts.

(A) (B)

Vapour

Vent

Feed

Steam

Steam

condensate

Thick liquor

FIGURE 6.6

Natural circulation evaporator with (A) horizontal tubes, (B) vertical tubes.

From Richardson, J.F., Harker, J.H., & Backhurst, J.R. Particle technology & separation processes (5th ed.). Coulson and

Richardson’s chemical engineering (Vol. 2). Butterworth-Heinemann.