Page 172 - Process Equipment and Plant Design Principles and Practices by Subhabrata Ray Gargi Das

P. 172

170 Chapter 6 Evaporators

relative velocity. The vapor and entrained liquor leaving the top bonnet of the evaporator enters a

separator tangentially to break any foam. This enables handling of foamy liquids. The feed enters the

tubes at nearly its boiling point. Subcooled feed makes the initial section act merely as a feed heater

that reduces the overall performance of the unit.

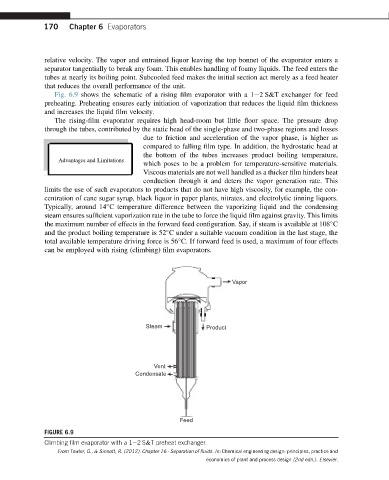

Fig. 6.9 shows the schematic of a rising film evaporator with a 1e2S&T exchanger for feed

preheating. Preheating ensures early initiation of vaporization that reduces the liquid film thickness

and increases the liquid film velocity.

The rising-film evaporator requires high head-room but little floor space. The pressure drop

through the tubes, contributed by the static head of the single-phase and two-phase regions and losses

due to friction and acceleration of the vapor phase, is higher as

compared to falling film type. In addition, the hydrostatic head at

the bottom of the tubes increases product boiling temperature,

Advantages and Limitations

which poses to be a problem for temperature-sensitive materials.

Viscous materials are not well handled as a thicker film hinders heat

conduction through it and deters the vapor generation rate. This

limits the use of such evaporators to products that do not have high viscosity, for example, the con-

centration of cane sugar syrup, black liquor in paper plants, nitrates, and electrolytic tinning liquors.

Typically, around 14 C temperature difference between the vaporizing liquid and the condensing

steam ensures sufficient vaporization rate in the tube to force the liquid film against gravity. This limits

the maximum number of effects in the forward feed configuration. Say, if steam is available at 108 C

and the product boiling temperature is 52 C under a suitable vacuum condition in the last stage, the

total available temperature driving force is 56 C. If forward feed is used, a maximum of four effects

can be employed with rising (climbing) film evaporators.

Vapor

Steam Product

Vent

Condensate

Feed

FIGURE 6.9

Climbing film evaporator with a 1e2S&T preheat exchanger.

From Towler, G., & Sinnott, R. (2012). Chapter 16 - Separation of fluids. In: Chemical engineering design: principles, practice and

economics of plant and process design (2nd edn.). Elsevier.