Page 233 - Process Modelling and Simulation With Finite Element Methods

P. 233

220 Process Modelling and Simulation with Finite Element Methods

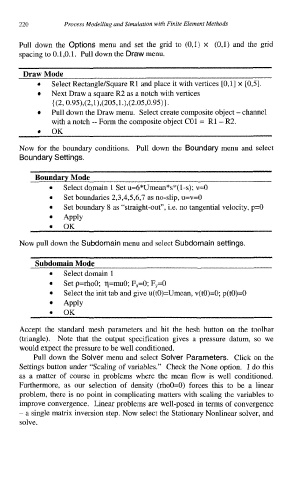

Pull down the Options menu and set the grid to @,I) x (0,l) and the grid

spacing to 0.1 ,O. 1. Pull down the Draw menu.

Draw Mode

0 Select RectangleKquare R1 and place it with vertices [0,1] x [O,5].

Next Draw a square R2 as a notch with vertices

{(2,0.95),(2,1),(205,1.),(2.05,O.95)}.

Pull down the Draw menu. Select create composite object - channel

with a notch -- Form the composite object CO1 = R1 - R2.

0 OK

Now for the boundary conditions. Pull down the Boundary menu and select

Boundary Settings.

Boundary Mode

0 Select domain 1 Set u=6*Umean*s*(l-s); v=O

0 Set boundaries 2,3,4,5,6,7 as no-slip, u=v=O

Set boundary 8 as “straight-out”, i.e. no tangential velocity, p=O

0

APPlY

0 OK

Now pull down the Subdomain menu and select Subdomain settings.

Subdomain Mode

Select domain 1

0

0 Set p=rhoO; q=muO; F,=O; F,=O

Select the init tab and give u(tO)=Umean, v(tO)=O; p(tO)=O

Apply

0 OK

Accept the standard mesh parameters and hit the hesh button on the toolbar

(triangle). Note that the output specification gives a pressure datum, so we

would expect the pressure to be well conditioned.

Pull down the Solver menu and select Solver Parameters. Click on the

Settings button under “Scaling of variables.” Check the None option. I do this

as a matter of course in problems where the mean flow is well conditioned.

Furthermore, as our selection of density (rhoO=O) forces this to be a linear

problem, there is no point in complicating matters with scaling the variables to

improve convergence. Linear problems are well-posed in terms of convergence

- a single matrix inversion step. Now select the Stationary Nonlinear solver, and

solve.