Page 315 - Process Modelling and Simulation With Finite Element Methods

P. 315

302 Process Modelling and Simulation with Finite Element Methods

mx I52

T,mp = 0 1

14

12

1

06

04

02

0

02

04

06

0681

MBX 109 0 738

1

06

04

06 4

02

0

0

02

3

05 04

M“ 0597 0 1 M,” 047s

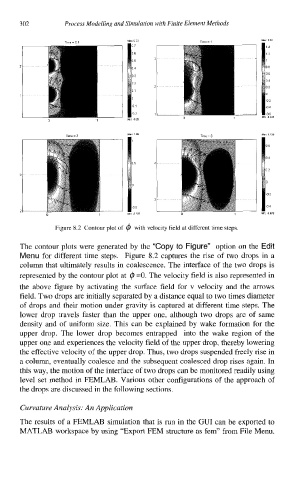

Figure 8.2 Contour plot of with velocity field at different time steps.

The contour plots were generated by the “Copy to Figure” option on the Edit

Menu for different time steps. Figure 8.2 captures the rise of two drops in a

column that ultimately results in coalescence. The interface of the two drops is

represented by the contour plot at @ =O. The velocity field is also represented in

the above figure by activating the surface field for v velocity and the arrows

field. Two drops are initially separated by a distance equal to two times diameter

of drops and their motion under gravity is captured at different time steps. The

lower drop travels faster than the upper one, although two drops are of same

density and of uniform size. This can be explained by wake formation for the

upper drop. The lower drop becomes entrapped into the wake region of the

upper one and experiences the velocity field of the upper drop, thereby lowering

the effective velocity of the upper drop. Thus, two drops suspended freely rise in

a column, eventually coalesce and the subsequent coalesced drop rises again. In

this way, the motion of the interface of two drops can be monitored readily using

level set method in FEMLAB. Various other configurations of the approach of

the drops are discussed in the following sections.

Curvature Analysis: An Application

The results of a FEMLAB simulation that is run in the GUI can be exported to

MATLAB workspace by using “Export FEM structure as fem” from File Menu.