Page 59 - Process simulation and control using Aspen

P. 59

52 PROCESS SIMULATION AND CO NTROL USING ASPEN

TABLE 1.6

Component Flow rate (kmol/hr)

n -pentane 10

ethanol 3

water 7 5

.

Applying the NRTL property method , simulate the decanter block to compute

the flow rates of two product streams.

1 . 10 A ternary mixture having the following flow rates is fed to a separator (Sep2) at

50oC and 5 bar (see Table 1.7).

TABLE 1.7

Component Flow rate (kmol/hr)

n-pentane 33.623

ethanol 0 . 476

water 3 .705

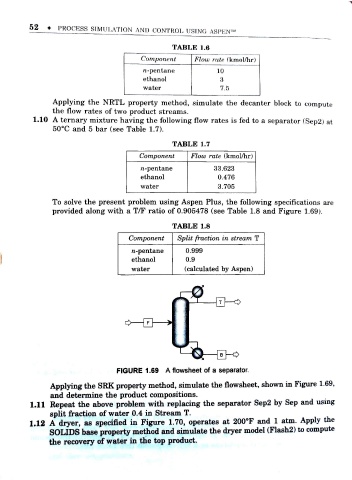

To solve the present problem using Aspen Plus, the following specifications are

provided along with a T/F ratio of 0.905478 (see Table 1.8 and Figure 1.69).

TABLE 1.8

Component Split fraction in stream T

n-pentane 0 . 999

ethanol 0 . 9

water (calculated by Aspen)

B -O

FIGURE 1.69 A flowsheet of a separator.

Applying the SRK property method, simulate the flowsheet, shown in Figure 1.69,

and determine the product compositions.

1 .11 Repeat the above problem with replacing the separator Sep2 by Sep and using

split fraction of water 0.4 in Stream T.

1 .12 A dryer, as specified in Figure 1.70, operates at 200 oF and 1 atm. Apply the

SOLIDS base property method and simulate the dryer model (Flash2) to compute

the recovery of water in the top product.