Page 415 - Reciprocating Compressors Operation Maintenance

P. 415

4OO Reciprocating Compressors: Operation and Maintenance

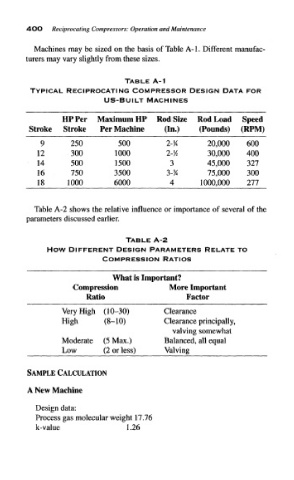

Machines may be sized on the basis of Table A-1. Different manufac-

turers may vary slightly from these sizes.

TABLE A-1

TYPICAL RECIPROCATING COMPRESSOR DESIGN DATA FOR

US-BUILT MACHINES

HP Per Maximum HP Rod Size Rod Load Speed

Stroke Stroke Per Machine (In.) (Pounds) (RPM)

9 250 500 2-% 20,000 600

12 300 1000 2-% 30,000 400

14 500 1500 3 45,000 327

16 750 3500 3-% 75,000 300

18 1000 6000 4 1000,000 277

Table A-2 shows the relative influence or importance of several of the

parameters discussed earlier.

TABLE A-2

How DIFFERENT DESIGN PARAMETERS RELATE TO

COMPRESSION RATIOS

What is Important?

Compression More Important

Ratio Factor

Very High (10-30) Clearance

High (8-10) Clearance principally,

valving somewhat

Moderate (5 Max.) Balanced, all equal

Low (2 or less) Valving

SAMPLE CALCULATION

A New Machine

Design data:

Process gas molecular weight 17.76

k-value 1,26