Page 119 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 119

and (2018) (2017) al. al. et (2012) al. (2012) al. (2009) al. al. et al. et (2014) al. al. et al. et

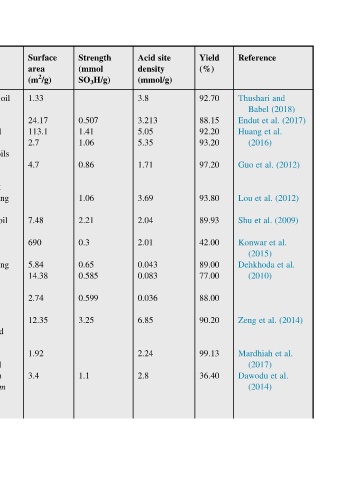

Reference Thushari Babel et Endut Huang (2016) et Guo et Lou et Shu Konwar (2015) Dehkhoda (2010) et Zeng Mardhiah (2017) Dawodu (2014)

Yield (%) 92.70 88.15 92.20 93.20 97.20 93.80 89.93 42.00 89.00 77.00 88.00 90.20 99.13 36.40

site

Acid density (mmol/g) 3.8 3.213 5.05 5.35 1.71 3.69 2.04 2.01 0.043 0.083 0.036 6.85 2.24 2.8

Strength (mmol SO 3 H/g) 0.507 1.41 1.06 0.86 1.06 2.21 0.3 0.65 0.585 0.599 3.25 1.1

Surface area (m 2 /g) 1.33 24.17 113.1 2.7 4.7 7.48 690 5.84 14.38 2.74 12.35 1.92 3.4

oil and oils cooking oil cooking oil

Feedstock palm Waste oil Palm Jatropha soybean blended Acidified soybean soapstock Waste oil Cottonseed acid Oleic Waste oil Refined cottonseed oil Jatropha curcas Calophyllum inophyllum oil

S time (h) 1 15 10 10 2 15 10 8 24 24 24 10 5 10

sulfonation. S temp ( C) 100 100 150 150 150 423 210 180 150 150 150 473 90 150

indirect C time (h) 5 4 20 2 1 0.5 1 15 4 5

by C temp 500 700

preparation ( C) 110 422 260 400 400 648 723 527 527 527 bark 723 350 400

Catalyst coconut meal shell De-alkaline lignin Xanthoceras sorbifolia hull bunge Sugarcane bagasse oil Vegetable asphalt Mesua seed L. ferrea Hardwood and Hardwood softwood wood shaving shell Jatropha seed curcas Calophyllum inophyllum seed

4.1 Biomass Deoiled Coconut Deoiled White and Peanut Deoiled Deoiled

Table S. No. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13.