Page 354 - Refining Biomass Residues for Sustainable Energy and Bioproducts

P. 354

(2018) (2018) (2018) (2018) (2016)

Amin (2016) (2016) (2015) (2016) (2016) (2016) (2016) (2013) (2017)

(2015) and al. (2014b) (2018) Yu (2014b) al. (2014a) (2017) (2018) al. al. al. al. (2016) Kim Kim Kim Kim al. (2017) al. al. et

al. Omar et al. et al. et and al. et et al. et al. al. et et et et al. and and and and et al. et et

et (2016) et et Elumalai Elumalai Elumalai Elumalai et Pulidindi Pulidindi Pulidindi Pulidindi Bevilaqua Rackemann

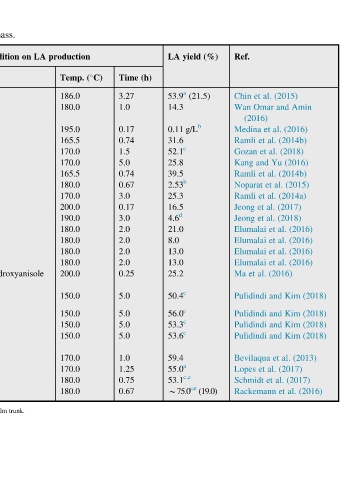

Ref. Chin Wan Medina Ramli Gozan Kang Ramli Noparat Ramli Jeong Jeong Ma Lopes Schmidt

(%)

yield (21.5) 0.11 g/L b B75.0 c,e (19.0)

LA 53.9 a 14.3 31.6 52.1 c 25.8 39.5 2.53 b 25.3 16.5 4.6 d 21.0 8.0 13.0 13.0 25.2 50.4 c 56.0 c 53.3 c 53.6 c 59.4 55.0 a 53.1 c,e

(h)

Time 3.27 1.0 0.17 0.74 1.5 5.0 0.74 0.67 3.0 0.17 3.0 2.0 2.0 2.0 2.0 0.25 5.0 5.0 5.0 5.0 1.0 1.25 0.75 0.67

( C)

production Temp. 186.0 180.0 195.0 165.5 170.0 170.0 165.5 180.0 170.0 200.0 190.0 180.0 180.0 180.0 180.0 200.0 150.0 150.0 150.0 150.0 170.0 170.0 180.0 180.0

LA

on

biomass. condition zeolite NaOH-zeolite H 2 SO 4 1 p-hydroxyanisole

lignocellulosic Reaction Catalyst H 2 SO 4 H 2 SO 4 H 2 SO 4 H 2 SO 4 H 2 SO 4 H 2 SO 4 Fe/HY H 2 SO 4 (aq.) HCl (aq.) HCl (aq.) HCl (aq.) HCl HCl HCl HCl HCl HCl H 2 SO 4 MSA MSA

pretreated Solvent H 2 O H 2 O H 2 O H 2 O H 2 O H 2 O H 2 O H 2 O H 2 O DMSO-THF DMSO-THF DMSO-THF DMSO-THF H 2 O H 2 O H 2 O H 2 O H 2 O H 2 O H 2 O H 2 O H 2 O

from (aq.) extraction EFB, Empty fruit bunch; MSA, methanesulfonic acid; OPF, oil palm frond; OPMF, oil palm mesocarp fiber; OPT, oil palm trunk.

production step explosion ammonia H 2 SO 4 explosion enzymatic aqueous

(LA) Pretreatment milling Ozone Steam [EMIM][Cl] in Soaking (aq.) H 2 SO 4 [EMIM][Cl] Diluted [BMIM][Br] (aq.) H 2 SO 4 (aq.) H 2 SO 4 Thermo-H 2 SO 4 Thermo-NaOH Thermo-NaCIO 2 Thermo-NaCIO Steam Na 2 CO 3 1 Na 2 S Na 2 CO 3 1 Na 2 S Na 2 CO 3 1 Na 2 S Na 2 CO 3 1 Na 2 S Soxhlet H 2 SO 4 1 NaOH Thermal-enz

acid Ball a Calculated based on cellulose percentage of biomass feedstock.

Levulinic feedstocks wood bagasse bagasse bagasse c Calculated based on C6/C5 sugar concentration.

14.4 straw straw straw straw straw straw stover sorghum bagasse husk b Product from pretreatment process. d LA from biomass hydrolysate. e Product in mol.%.

Table Biomass EFB EFB EFB EFB EFB Eucalyptus Kenaf OPT OPF Oak Oak Rice Rice Rice Rice Rice Rice Corn Miscanthus Sweet Rice Sugarcane Sugarcane Sugarcane