Page 139 - Robot Builder's Bonanza

P. 139

108 WORKING WITH METAL

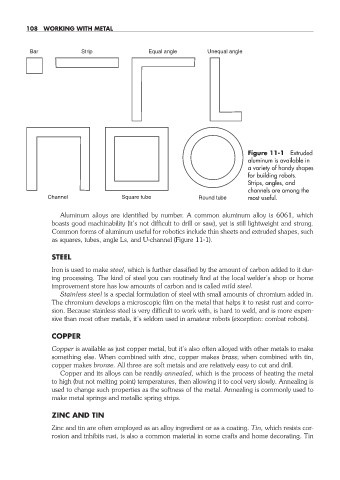

Bar Strip Equal angle Unequal angle

Figure 11-1 Extruded

aluminum is available in

a variety of handy shapes

for building robots.

Strips, angles, and

channels are among the

Channel Square tube Round tube most useful.

Aluminum alloys are identified by number. A common aluminum alloy is 6061, which

boasts good machinability (it’s not difficult to drill or saw), yet is still lightweight and strong.

Common forms of aluminum useful for robotics include thin sheets and extruded shapes, such

as squares, tubes, angle Ls, and U- channel (Figure 11-1).

STEEL

Iron is used to make steel, which is further classified by the amount of carbon added to it dur-

ing processing. The kind of steel you can routinely find at the local welder’s shop or home

improvement store has low amounts of carbon and is called mild steel.

Stainless steel is a special formulation of steel with small amounts of chromium added in.

The chromium develops a microscopic film on the metal that helps it to resist rust and corro-

sion. Because stainless steel is very difficult to work with, is hard to weld, and is more expen-

sive than most other metals, it’s seldom used in amateur robots (exception: combat robots).

COPPER

Copper is available as just copper metal, but it’s also often alloyed with other metals to make

something else. When combined with zinc, copper makes brass; when combined with tin,

copper makes bronze. All three are soft metals and are relatively easy to cut and drill.

Copper and its alloys can be readily annealed, which is the process of heating the metal

to high (but not melting point) temperatures, then allowing it to cool very slowly. Annealing is

used to change such properties as the softness of the metal. Annealing is commonly used to

make metal springs and metallic spring strips.

ZINC AND TIN

Zinc and tin are often employed as an alloy ingredient or as a coating. Tin, which resists cor-

rosion and inhibits rust, is also a common material in some crafts and home decorating. Tin

11-chapter-11.indd 108 4/21/11 11:45 AM