Page 247 - Robot Builder's Bonanza

P. 247

216 MOVING YOUR ROBOT

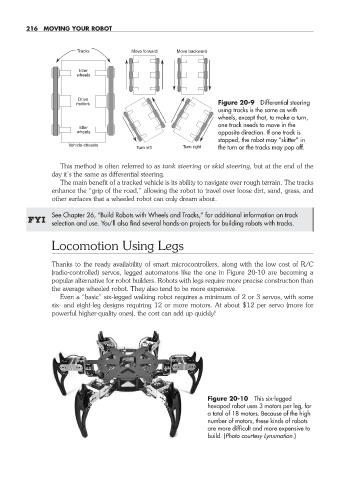

Tracks Move forward Move backward

Idler

wheels

Drive

motors Figure 20- 9 Differential steering

using tracks is the same as with

wheels, except that, to make a turn,

one track needs to move in the

Idler

wheels opposite direction. If one track is

stopped, the robot may “skitter” in

Vehicle chassis

Turn left Turn right the turn or the tracks may pop off.

This method is often referred to as tank steering or skid steering, but at the end of the

day it’s the same as differential steering.

The main benefit of a tracked vehicle is its ability to navigate over rough terrain. The tracks

enhance the “grip of the road,” allowing the robot to travel over loose dirt, sand, grass, and

other surfaces that a wheeled robot can only dream about.

See Chapter 26, “Build Robots with Wheels and Tracks,” for additional information on track

FYI selection and use. You’ll also find several hands- on projects for building robots with tracks.

Locomotion Using Legs

Thanks to the ready availability of smart microcontrollers, along with the low cost of R/C

(radio- controlled) servos, legged automatons like the one in Figure 20- 10 are becoming a

popular alternative for robot builders. Robots with legs require more precise construction than

the average wheeled robot. They also tend to be more expensive.

Even a “basic” six- legged walking robot requires a minimum of 2 or 3 servos, with some

six- and eight- leg designs requiring 12 or more motors. At about $12 per servo (more for

powerful higher- quality ones), the cost can add up quickly!

Figure 20- 10 This six- legged

hexapod robot uses 3 motors per leg, for

a total of 18 motors. Because of the high

number of motors, these kinds of robots

are more difficult and more expensive to

build. (Photo courtesy Lynxmotion.)

20-chapter-20.indd 216 4/21/11 11:50 AM