Page 246 - Robot Builder's Bonanza

P. 246

LOCOMOTION USING TRACKS 215

drive wheel can be accomplished by separate steering motors or by one steering motor that is

linked— via a chain or cogged belt— to all of the drive wheels.

Locomotion Using Tracks

Since World War I the tank has become the symbol of military battles. The hulking mass of

iron plowing over the earth, the shrieking sound of metal crushing against the ground, the

blasts of fire from its cannon, all combine a sense of awe and respect. Little wonder that the

tank design is popular among robot builders. The same principles that make a military tank

superior for uneven terrain apply to robots or, in fact, any other type of treaded vehicle.

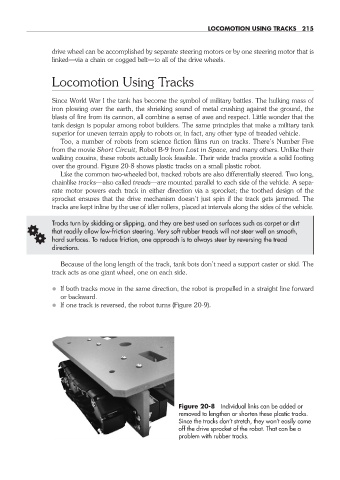

Too, a number of robots from science fiction films run on tracks. There’s Number Five

from the movie Short Circuit, Robot B- 9 from Lost in Space, and many others. Unlike their

walking cousins, these robots actually look feasible. Their wide tracks provide a solid footing

over the ground. Figure 20- 8 shows plastic tracks on a small plastic robot.

Like the common two- wheeled bot, tracked robots are also differentially steered. Two long,

chainlike tracks— also called treads— are mounted parallel to each side of the vehicle. A sepa-

rate motor powers each track in either direction via a sprocket; the toothed design of the

sprocket ensures that the drive mechanism doesn’t just spin if the track gets jammed. The

tracks are kept inline by the use of idler rollers, placed at intervals along the sides of the vehicle.

Tracks turn by skidding or slipping, and they are best used on surfaces such as carpet or dirt

G that readily allow low- friction steering. Very soft rubber treads will not steer well on smooth,

hard surfaces. To reduce friction, one approach is to always steer by reversing the tread

directions.

Because of the long length of the track, tank bots don’t need a support caster or skid. The

track acts as one giant wheel, one on each side.

• If both tracks move in the same direction, the robot is propelled in a straight line forward

or backward.

• If one track is reversed, the robot turns (Figure 20- 9).

Figure 20- 8 Individual links can be added or

removed to lengthen or shorten these plastic tracks.

Since the tracks don’t stretch, they won’t easily come

off the drive sprocket of the robot. That can be a

problem with rubber tracks.

20-chapter-20.indd 215 4/21/11 11:50 AM