Page 198 - Robot Builders Source Book - Gordon McComb

P. 198

186 Feedback Sensors

device measures the difference between the initial distance (between the nozzles) and

the distance as affected by either the thickness of the strip or the diameter of the holes.

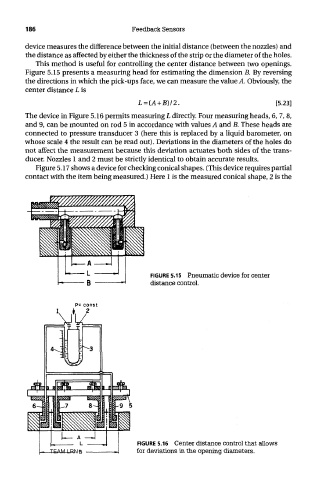

This method is useful for controlling the center distance between two openings.

Figure 5.15 presents a measuring head for estimating the dimension B. By reversing

the directions in which the pick-ups face, we can measure the value A Obviously, the

center distance I is

The device in Figure 5.16 permits measuring I directly. Four measuring heads, 6, 7, 8,

and 9, can be mounted on rod 5 in accordance with values A and B. These heads are

connected to pressure transducer 3 (here this is replaced by a liquid barometer, on

whose scale 4 the result can be read out). Deviations in the diameters of the holes do

not affect the measurement because this deviation actuates both sides of the trans-

ducer. Nozzles 1 and 2 must be strictly identical to obtain accurate results.

Figure 5.17 shows a device for checking conical shapes. (This device requires partial

contact with the item being measured.) Here 1 is the measured conical shape, 2 is the

FIGURE 5.15 Pneumatic device for center

distance control.

FIGURE 5.16 Center distance control that allows

TEAM LRN for deviations in the opening diameters.