Page 200 - Robot Builders Source Book - Gordon McComb

P. 200

188 Feedback Sensors

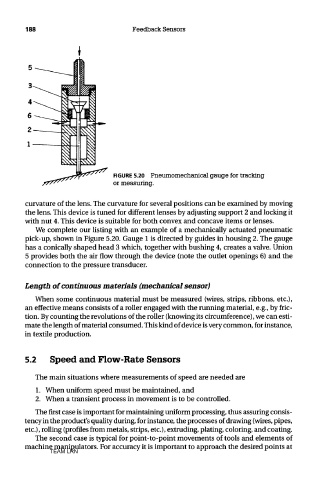

FIGURE 5.20 Pneumomechanical gauge for tracking

or measuring.

curvature of the lens. The curvature for several positions can be examined by moving

the lens. This device is tuned for different lenses by adjusting support 2 and locking it

with nut 4. This device is suitable for both convex and concave items or lenses.

We complete our listing with an example of a mechanically actuated pneumatic

pick-up, shown in Figure 5.20. Gauge 1 is directed by guides in housing 2. The gauge

has a conically shaped head 3 which, together with bushing 4, creates a valve. Union

5 provides both the air flow through the device (note the outlet openings 6) and the

connection to the pressure transducer.

Length of continuous materials (mechanical sensor)

When some continuous material must be measured (wires, strips, ribbons, etc.),

an effective means consists of a roller engaged with the running material, e.g., by fric-

tion. By counting the revolutions of the roller (knowing its circumference), we can esti-

mate the length of material consumed. This kind of device is very common, for instance,

in textile production.

5.2 Speed and Flow-Rate Sensors

The main situations where measurements of speed are needed are

1. When uniform speed must be maintained, and

2. When a transient process in movement is to be controlled.

The first case is important for maintaining uniform processing, thus assuring consis-

tency in the product's quality during, for instance, the processes of drawing (wires, pipes,

etc.), rolling (profiles from metals, strips, etc.), extruding, plating, coloring, and coating.

The second case is typical for point-to-point movements of tools and elements of

machine manipulators. For accuracy it is important to approach the desired points at

TEAM LRN