Page 205 - Robot Builders Source Book - Gordon McComb

P. 205

5.3 Force Sensors 193

5.3 Force Sensors

Considering force measurements, we will discuss pure force sensors, as well as

acceleration and pressure pick-ups. Obviously, acceleration can be derived from mea-

sured speed by differentiation. However, as is known, this entails loss of accuracy (the

opposite, integration of acceleration to obtain speed and distance values, is more accu-

rate). This is one of the reasons for using force measurements based on Newton's law

for acceleration transducers.

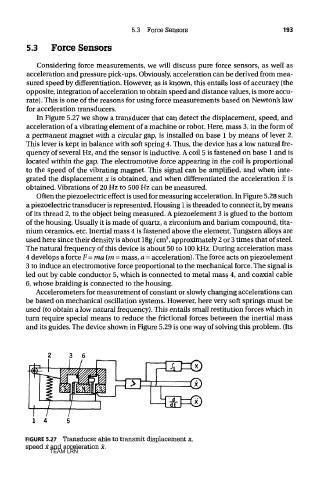

In Figure 5.27 we show a transducer that can detect the displacement, speed, and

acceleration of a vibrating element of a machine or robot. Here, mass 3, in the form of

a permanent magnet with a circular gap, is installed on base 1 by means of lever 2.

This lever is kept in balance with soft spring 4. Thus, the device has a low natural fre-

quency of several Hz, and the sensor is inductive. A coil 5 is fastened on base 1 and is

located within the gap. The electromotive force appearing in the coil is proportional

to the speed of the vibrating magnet. This signal can be amplified, and when inte-

grated the displacement x is obtained, and when differentiated the acceleration x is

obtained. Vibrations of 20 Hz to 500 Hz can be measured.

Often the piezoelectric effect is used for measuring acceleration. In Figure 5.28 such

a piezoelectric transducer is represented. Housing 1 is threaded to connect it, by means

of its thread 2, to the object being measured. A piezoelement 3 is glued to the bottom

of the housing. Usually it is made of quartz, a zirconium and barium compound, tita-

nium ceramics, etc. Inertial mass 4 is fastened above the element. Tungsten alloys are

3

used here since their density is about 18g/cm , approximately 2 or 3 times that of steel.

The natural frequency of this device is about 50 to 100 kHz. During acceleration mass

4 develops a force F= ma (m = mass, a = acceleration). The force acts on piezoelement

3 to induce an electromotive force proportional to the mechanical force. The signal is

led out by cable conductor 5, which is connected to metal mass 4, and coaxial cable

6, whose braiding is connected to the housing.

Accelerometers for measurement of constant or slowly changing accelerations can

be based on mechanical oscillation systems. However, here very soft springs must be

used (to obtain a low natural frequency). This entails small restitution forces which in

turn require special means to reduce the frictional forces between the inertial mass

and its guides. The device shown in Figure 5.29 is one way of solving this problem. (Its

FIGURE 5.27 Transducer able to transmit displacement x,

speed x and acceleration x.

TEAM LRN