Page 216 - Robot Builders Source Book - Gordon McComb

P. 216

204 Feedback Sensors

a human worker. Here, interruption of the light beam attests to the presence of a part

on its place. Sometimes it is necessary to check for the absence of any kind of conta-

minant in certain places—a piece of a chip, a dropped bolt, screw, or nut, etc. This

method also permits checking whether the correct part is placed in a certain socket.

For this purpose elements of the geometrical shape of the part—holes, slots, planes—

would serve as markers.

Pneumatic sensors also can be used for checking part presence. As explained in

Section 5.1 (2), pneumatic sensors can work without contacting the measured surface.

Thus, in Figure 5.12b), when there is no element 2 near nozzle 1, the pressure in the

device would drop. In this case high accuracy is not required, and the device is used

in the "on-off" regime.

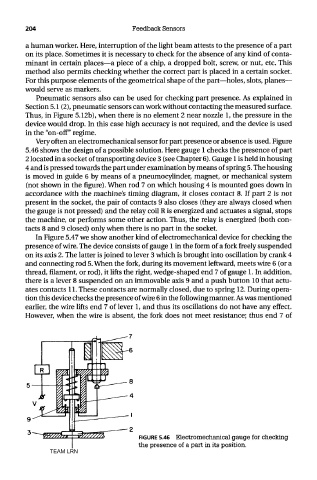

Very often an electromechanical sensor for part presence or absence is used. Figure

5.46 shows the design of a possible solution. Here gauge 1 checks the presence of part

2 located in a socket of transporting device 3 (see Chapter 6). Gauge 1 is held in housing

4 and is pressed towards the part under examination by means of spring 5. The housing

is moved in guide 6 by means of a pneumocylinder, magnet, or mechanical system

(not shown in the figure). When rod 7 on which housing 4 is mounted goes down in

accordance with the machine's timing diagram, it closes contact 8. If part 2 is not

present in the socket, the pair of contacts 9 also closes (they are always closed when

the gauge is not pressed) and the relay coil R is energized and actuates a signal, stops

the machine, or performs some other action. Thus, the relay is energized (both con-

tacts 8 and 9 closed) only when there is no part in the socket.

In Figure 5.47 we show another kind of electromechanical device for checking the

presence of wire. The device consists of gauge 1 in the form of a fork freely suspended

on its axis 2. The latter is joined to lever 3 which is brought into oscillation by crank 4

and connecting rod 5. When the fork, during its movement leftward, meets wire 6 (or a

thread, filament, or rod), it lifts the right, wedge-shaped end 7 of gauge 1. In addition,

there is a lever 8 suspended on an immovable axis 9 and a push button 10 that actu-

ates contacts 11. These contacts are normally closed, due to spring 12. During opera-

tion this device checks the presence of wire 6 in the following manner. As was mentioned

earlier, the wire lifts end 7 of lever 1, and thus its oscillations do not have any effect.

However, when the wire is absent, the fork does not meet resistance; thus end 7 of

FIGURE 5.46 Electromechanical gauge for checking

the presence of a part in its position.

TEAM LRN