Page 55 - Robot Builders Source Book - Gordon McComb

P. 55

44 Concepts and Layouts

a correspondingly shaped electromagnet are inserted into these cavities from

below. The electric coil of the electromagnet is fed by an alternating current of

say 50 or 60 Hz. The tin creates a secondary wind in which the current reaches

very high values (recall that the ratio of the currents in the two coils is inversely

proportional to the number of winds in every coil). This current heats the tin

and brings it to the melting point. On the other hand, due to the electromag-

netic forces which appear as a result of the interaction between the alternating

current and the magnetic field, molten tin is thrown out of the gap between the

protuberances, creating a steady wave of fresh (clean) tin.

Example 5

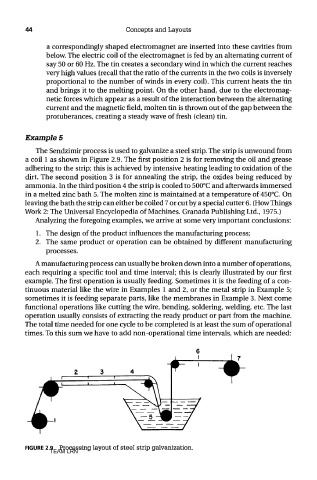

The Sendzimir process is used to galvanize a steel strip. The strip is unwound from

a coil 1 as shown in Figure 2.9. The first position 2 is for removing the oil and grease

adhering to the strip; this is achieved by intensive heating leading to oxidation of the

dirt. The second position 3 is for annealing the strip, the oxides being reduced by

ammonia. In the third position 4 the strip is cooled to 500°C and afterwards immersed

in a melted zinc bath 5. The molten zinc is maintained at a temperature of 450°C. On

leaving the bath the strip can either be coiled 7 or cut by a special cutter 6. (HowThings

Work 2: The Universal Encyclopedia of Machines. Granada Publishing Ltd., 1975.)

Analyzing the foregoing examples, we arrive at some very important conclusions:

1. The design of the product influences the manufacturing process;

2. The same product or operation can be obtained by different manufacturing

processes.

A manufacturing process can usually be broken down into a number of operations,

each requiring a specific tool and time interval; this is clearly illustrated by our first

example. The first operation is usually feeding. Sometimes it is the feeding of a con-

tinuous material like the wire in Examples 1 and 2, or the metal strip in Example 5;

sometimes it is feeding separate parts, like the membranes in Example 3. Next come

functional operations like cutting the wire, bending, soldering, welding, etc. The last

operation usually consists of extracting the ready product or part from the machine.

The total time needed for one cycle to be completed is at least the sum of operational

times. To this sum we have to add non-operational time intervals, which are needed:

FIGURE 2.9 Processing layout of steel strip galvanization.

TEAM LRN