Page 197 - Robotics Designing the Mechanisms for Automated Machinery

P. 197

5.1 Linear and Angular Displacement Sensors 185

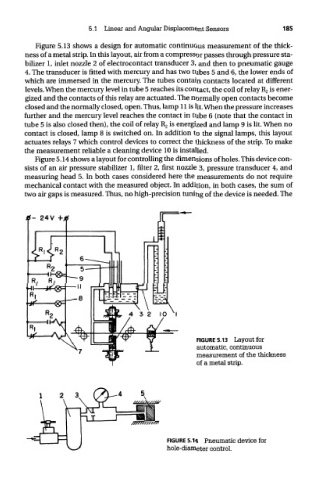

Figure 5.13 shows a design for automatic continuous measurement of the thick-

ness of a metal strip. In this layout, air from a compressor passes through pressure sta-

bilizer 1, inlet nozzle 2 of electrocontact transducer 3, and then to pneumatic gauge

4. The transducer is fitted with mercury and has two tubes 5 and 6, the lower ends of

which are immersed in the mercury. The tubes contain contacts located at different

levels. When the mercury level in tube 5 reaches its contact, the coil of relay R 2 is ener-

gized and the contacts of this relay are actuated. The normally open contacts become

closed and the normally closed, open. Thus, lamp 11 is lit. When the pressure increases

further and the mercury level reaches the contact in tube 6 (note that the contact in

tube 5 is also closed then), the coil of relay R 2 is energized and lamp 9 is lit. When no

contact is closed, lamp 8 is switched on. In addition to the signal lamps, this layout

actuates relays 7 which control devices to correct the thickness of the strip. To make

the measurement reliable a cleaning device 10 is installed.

Figure 5.14 shows a layout for controlling the dimensions of holes. This device con-

sists of an air pressure stabilizer 1, filter 2, first nozzle 3, pressure transducer 4, and

measuring head 5. In both cases considered here the measurements do not require

mechanical contact with the measured object. In addition, in both cases, the sum of

two air gaps is measured. Thus, no high-precision tuning of the device is needed. The

FIGURE 5.13 Layout for

automatic, continuous

measurement of the thickness

of a metal strip.

FIGURE 5.14 Pneumatic device for

hole-diameter control.