Page 192 - Robotics Designing the Mechanisms for Automated Machinery

P. 192

180 Feedback Sensors

magnetic flux. Armature 4 is mounted on rod 5, which serves as a pick-up for the dis-

placement jc. (The rod is made of a nonmagnetic material.) The magnetic flux is divided

into two loops going through the coils and armature 4. The length of the armature's

sections in each loop determines the inductive reactance of each coil. Thus, these coils,

which are a part of a bridge, change its balance (as in the case presented in Figure

5.1b)). Induction sensors are usually limited to measuring ranges not larger than, say,

3 4

15-20 mm. However, the accuracy is on the order of 10 -10 mm.

Another useful modification of an induction position sensor is shown in Figure 5.7.

Here a lead screw 1 with a certain pitch (large enough to suit the design) and profile

interacts with an induction pick-up 2. The alternating current resistance of its coil 3

depends on the relative position (see the above explanations) of the thread and the

poles of the magnetic core. Thus, fractions of the screw's revolution can be measured.

This design is thus made very effective.

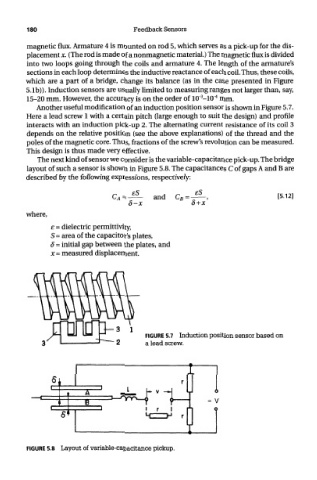

The next kind of sensor we consider is the variable-capacitance pick-up. The bridge

layout of such a sensor is shown in Figure 5.8. The capacitances C of gaps A and B are

described by the following expressions, respectively:

where,

s = dielectric permittivity,

S = area of the capacitor's plates,

S = initial gap between the plates, and

jc = measured displacement.

FIGURE 5.7 Induction position sensor based on

a lead screw.

FIGURE 5.8 Layout of variable-capacitance pickup.