Page 189 - Robotics Designing the Mechanisms for Automated Machinery

P. 189

5.1 Linear and Angular Displacement Sensors 177

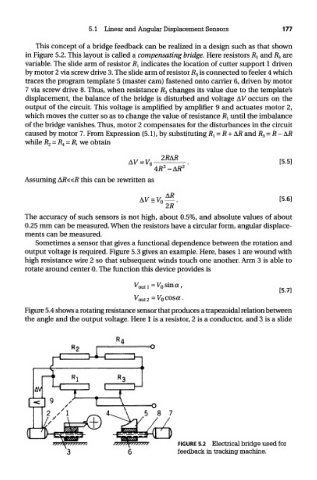

This concept of a bridge feedback can be realized in a design such as that shown

in Figure 5.2. This layout is called a compensating bridge. Here resistors R^ and R 3 are

variable. The slide arm of resistor R l indicates the location of cutter support 1 driven

by motor 2 via screw drive 3. The slide arm of resistor R 3 is connected to feeler 4 which

traces the program template 5 (master cam) fastened onto carrier 6, driven by motor

7 via screw drive 8. Thus, when resistance R 3 changes its value due to the template's

displacement, the balance of the bridge is disturbed and voltage AV" occurs on the

output of the circuit. This voltage is amplified by amplifier 9 and actuates motor 2,

which moves the cutter so as to change the value of resistance R 1 until the imbalance

of the bridge vanishes. Thus, motor 2 compensates for the disturbances in the circuit

caused by motor 7. From Expression (5.1), by substituting J? x = R + AR and R 3 = R-AR

while R 2 = R 4 = R, we obtain

Assuming AR«R this can be rewritten as

The accuracy of such sensors is not high, about 0.5%, and absolute values of about

0.25 mm can be measured. When the resistors have a circular form, angular displace-

ments can be measured.

Sometimes a sensor that gives a functional dependence between the rotation and

output voltage is required. Figure 5.3 gives an example. Here, bases 1 are wound with

high resistance wire 2 so that subsequent winds touch one another. Arm 3 is able to

rotate around center 0. The function this device provides is

Figure 5.4 shows a rotating resistance sensor that produces a trapezoidal relation between

the angle and the output voltage. Here 1 is a resistor, 2 is a conductor, and 3 is a slide

FIGURE 5.2 Electrical bridge used for

feedback in tracking machine.