Page 138 - Rock Mechanics For Underground Mining

P. 138

ROCK STRENGTH AND DEFORMABILITY

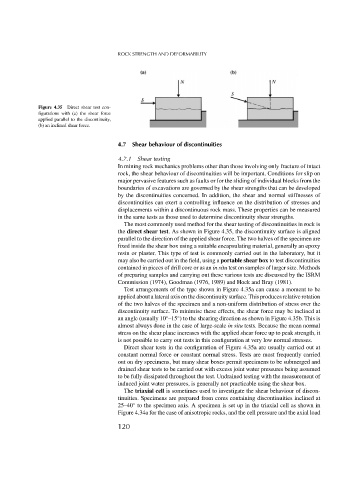

Figure 4.35 Direct shear test con-

figurations with (a) the shear force

applied parallel to the discontinuity,

(b) an inclined shear force.

4.7 Shear behaviour of discontinuities

4.7.1 Shear testing

In mining rock mechanics problems other than those involving only fracture of intact

rock, the shear behaviour of discontinuities will be important. Conditions for slip on

major pervasive features such as faults or for the sliding of individual blocks from the

boundaries of excavations are governed by the shear strengths that can be developed

by the discontinuities concerned. In addition, the shear and normal stiffnesses of

discontinuities can exert a controlling influence on the distribution of stresses and

displacements within a discontinuous rock mass. These properties can be measured

in the same tests as those used to determine discontinuity shear strengths.

The most commonly used method for the shear testing of discontinuities in rock is

the direct shear test. As shown in Figure 4.35, the discontinuity surface is aligned

parallel to the direction of the applied shear force. The two halves of the specimen are

fixed inside the shear box using a suitable encapsulating material, generally an epoxy

resin or plaster. This type of test is commonly carried out in the laboratory, but it

may also be carried out in the field, using a portable shear box to test discontinuities

contained in pieces of drill core or as an in situ test on samples of larger size. Methods

of preparing samples and carrying out these various tests are discussed by the ISRM

Commission (1974), Goodman (1976, 1989) and Hoek and Bray (1981).

Test arrangements of the type shown in Figure 4.35a can cause a moment to be

applied about a lateral axis on the discontinuity surface. This produces relative rotation

of the two halves of the specimen and a non-uniform distribution of stress over the

discontinuity surface. To minimise these effects, the shear force may be inclined at

an angle (usually 10 –15 ) to the shearing direction as shown in Figure 4.35b. This is

◦

◦

almost always done in the case of large-scale in situ tests. Because the mean normal

stress on the shear plane increases with the applied shear force up to peak strength, it

is not possible to carry out tests in this configuration at very low normal stresses.

Direct shear tests in the configuration of Figure 4.35a are usually carried out at

constant normal force or constant normal stress. Tests are most frequently carried

out on dry specimens, but many shear boxes permit specimens to be submerged and

drained shear tests to be carried out with excess joint water pressures being assumed

to be fully dissipated throughout the test. Undrained testing with the measurement of

induced joint water pressures, is generally not practicable using the shear box.

The triaxial cell is sometimes used to investigate the shear behaviour of discon-

tinuities. Specimens are prepared from cores containing discontinuities inclined at

◦

25–40 to the specimen axis. A specimen is set up in the triaxial cell as shown in

Figure 4.34a for the case of anisotropic rocks, and the cell pressure and the axial load

120