Page 139 - Rock Mechanics For Underground Mining

P. 139

SHEAR BEHAVIOUR OF DISCONTINUITIES

are applied successively. The triaxial cell is well suited to testing discontinuities in the

presence of water. Tests may be either drained or undrained, preferably with a known

level of joint water pressure being imposed and maintained throughout the test.

It is assumed that slip on the discontinuity will occur according to the theory set

out in section 4.6. Mohr circle plots are made of the total or effective stresses at slip

at a number of values of 3 , and the points on these circles giving the stresses on the

plane of the discontinuity are identified. The required shear strength envelope is then

drawn through these points. This requires that a number of tests be carried out on

similar discontinuities.

In an attempt to overcome the need to obtain, prepare and set up several specimens

containing similar discontinuities, a stage testing procedure is sometimes used. A

specimen is tested at a low confining pressure as outlined above. When it appears that

slip on the discontinuity has just been initiated (represented by a flattening of the axial

load–axial displacement curve that must be continuously recorded throughout each

test), loading is stopped, the cell pressure is increased to a new value, and loading

is recommenced. By repeating this process several times, a number of points on the

peak strength envelope of the discontinuity can be obtained from the one specimen.

However, this approach exacerbates the major difficulty involved in using the triaxial

test to determine discontinuity shear strengths, namely the progressive change in the

geometry of the cell–specimen system that accompanies shear displacement on the

discontinuity.

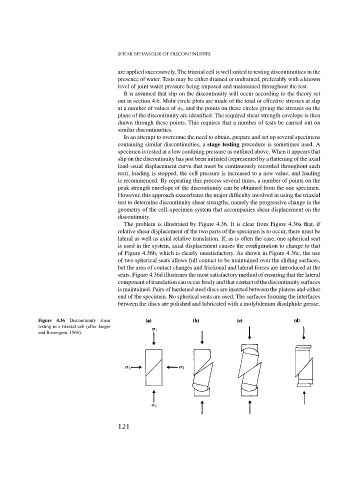

The problem is illustrated by Figure 4.36. It is clear from Figure 4.36a that, if

relative shear displacement of the two parts of the specimen is to occur, there must be

lateral as well as axial relative translation. If, as is often the case, one spherical seat

is used in the system, axial displacement causes the configuration to change to that

of Figure 4.36b, which is clearly unsatisfactory. As shown in Figure 4.36c, the use

of two spherical seats allows full contact to be maintained over the sliding surfaces,

but the area of contact changes and frictional and lateral forces are introduced at the

seats. Figure 4.36d illustrates the most satisfactory method of ensuring that the lateral

componentoftranslationcanoccurfreelyandthatcontactofthediscontinuitysurfaces

is maintained. Pairs of hardened steel discs are inserted between the platens and either

end of the specimen. No spherical seats are used. The surfaces forming the interfaces

between the discs are polished and lubricated with a molybdenum disulphide grease.

Figure 4.36 Discontinuity shear

testing in a triaxial cell (after Jaeger

and Rosengren, 1969).

121