Page 481 - Rock Mechanics For Underground Mining

P. 481

SUBLEVEL CAVING

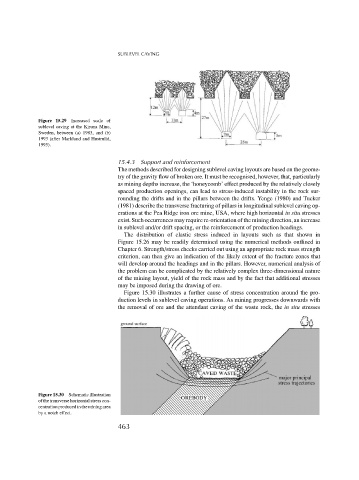

Figure 15.29 Increased scale of

sublevel caving at the Kiruna Mine,

Sweden, between (a) 1983, and (b)

1993 (after Marklund and Hustrulid,

1995).

15.4.3 Support and reinforcement

The methods described for designing sublevel caving layouts are based on the geome-

try of the gravity flow of broken ore. It must be recognised, however, that, particularly

as mining depths increase, the ‘honeycomb’ effect produced by the relatively closely

spaced production openings, can lead to stress-induced instability in the rock sur-

rounding the drifts and in the pillars between the drifts. Yenge (1980) and Tucker

(1981) describe the transverse fracturing of pillars in longitudinal sublevel caving op-

erations at the Pea Ridge iron ore mine, USA, where high horizontal in situ stresses

exist. Such occurrences may require re-orientation of the mining direction, an increase

in sublevel and/or drift spacing, or the reinforcement of production headings.

The distribution of elastic stress induced in layouts such as that shown in

Figure 15.26 may be readily determined using the numerical methods outlined in

Chapter 6. Strength/stress checks carried out using an appropriate rock mass strength

criterion, can then give an indication of the likely extent of the fracture zones that

will develop around the headings and in the pillars. However, numerical analysis of

the problem can be complicated by the relatively complex three-dimensional nature

of the mining layout, yield of the rock mass and by the fact that additional stresses

may be imposed during the drawing of ore.

Figure 15.30 illustrates a further cause of stress concentration around the pro-

duction levels in sublevel caving operations. As mining progresses downwards with

the removal of ore and the attendant caving of the waste rock, the in situ stresses

Figure 15.30 Schematic illustration

of the transverse horizontal stress con-

centration produced in the mining area

by a notch effect.

463