Page 146 - Root Cause Failure Analysis

P. 146

134 Root Cause Failure Analysis

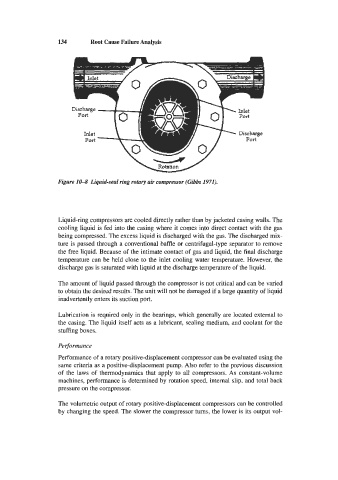

Figur *e 10-8 Liquidseal ring rotary air compressor (Gibbs 1971).

Liquid-ring compressors are cooled directly rather than by jacketed casing walls. The

cooling liquid is fed into the casing where it comes into direct contact with the gas

being compressed. The excess liquid is discharged with the gas. The discharged mix-

ture is passed through a conventional baffle or centrifugal-type separator to remove

the free liquid. Because of the intimate contact of gas and liquid, the final discharge

temperature can be held close to the inlet cooling water temperature. However, the

discharge gas is saturated with liquid at the discharge temperature of the liquid.

The amount of liquid passed through the compressor is not critical and can be varied

to obtain the desired results. The unit will not be damaged if a large quantity of liquid

inadvertently enters its suction port.

Lubrication is required only in the bearings, which generally are located external to

the casing. The liquid itself acts as a lubricant, sealing medium, and coolant for the

stuffing boxes.

Per$ormance

Performance of a rotary positive-displacement compressor can be evaluated using the

same criteria as a positive-displacement pump. Also refer to the previous discussion

of the laws of thermodynamics that apply to all compressors. As constant-volume

machines, performance is determined by rotation speed, internal slip, and total back

pressure on the compressor.

The volumetric output of rotary positive-displacement compressors can be controlled

by changing the speed. The slower the compressor turns, the lower is its output vol-