Page 223 - Root Cause Failure Analysis

P. 223

Control Valves 21 1

One Way

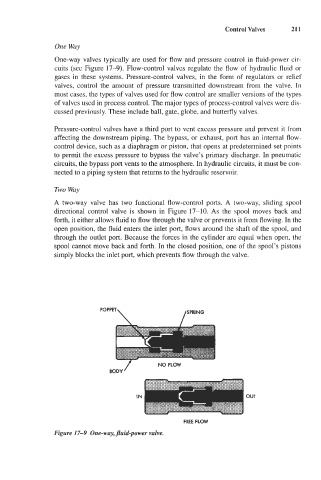

One-way valves typically are used for flow and pressure control in fluid-power cir-

cuits (see Figure 17-9). Flow-control valves regulate the flow of hydraulic fluid or

gases in these systems. Pressure-control valves, in the form of regulators or relief

valves, control the amount of pressure transmitted downstream from the valve. In

most cases, the types of valves used for flow control are smaller versions of the types

of valves used in process control. The major types of process-control valves were dis-

cussed previously. These include ball, gate, globe, and butterfly valves.

Pressure-control valves have a third port to vent excess pressure and prevent it from

affecting the downstream piping. The bypass, or exhaust, port has an internal flow-

control device, such as a diaphragm or piston, that opens at predetermined set points

to permit the excess pressure to bypass the valve’s primary discharge. In pneumatic

circuits, the bypass port vents to the atmosphere. In hydraulic circuits, it must be con-

nected to a piping system that returns to the hydraulic reservoir.

Two Way

A two-way valve has two functional flow-control ports. A two-way, sliding spool

directional control valve is shown in Figure 17-10. As the spool moves back and

forth, it either allows fluid to flow through the valve or prevents it from flowing. In the

open position, the fluid enters the inlet port, flows around the shaft of the spool, and

through the outlet port. Because the forces in the cylinder are equal when open, the

spool cannot move back and forth. In the closed position, one of the spool’s pistons

simply blocks the inlet port, which prevents flow through the valve.

/SPRING

BODY / NO FLOW

IN OUT

FREE FLOW

Figure 17-9 One-way, fluidpower valve.