Page 218 - Root Cause Failure Analysis

P. 218

206 Root Cause Failure Analysis

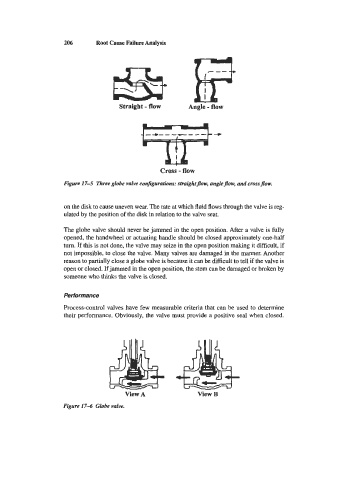

Straight - flow Angle - flow

Cross - flow

Figure 17-5 Three globe valve configurations: straightjlow, angle flow, and cross &w.

on the disk to cause uneven wear. The rate at which fluid flows through the valve is reg-

ulated by the position of the disk in relation to the valve seat.

The globe valve should never be jammed in the open position. After a valve is fully

opened, the handwheel or actuating handle should be closed approximately one-half

turn. If this is not done, the valve may seize in the open position making it difficult, if

not impossible, to close the valve. Many valves are damaged in the manner. Another

reason to partially close a globe valve is because it can be difficult to tell if the valve is

open or closed. If jammed in the open position, the stem can be damaged or broken by

someone who thinks the valve is closed.

Performance

Process-control valves have few measurable criteria that can be used to determine

their performance. Obviously, the valve must provide a positive seal when closed.

View A View B

Figure 17-6 Globe valve.