Page 215 - Root Cause Failure Analysis

P. 215

Control Valves 203

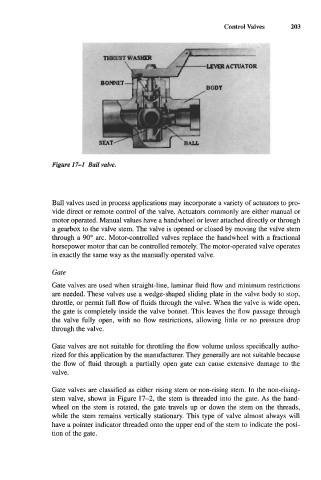

Figure 17-1 Ball valve.

Ball valves used in process applications may incorporate a variety of actuators to pro-

vide direct or remote control of the valve. Actuators commonly are either manual or

motor operated. Manual values have a handwheel or lever attached directly or through

a gearbox to the valve stem. The valve is opened or closed by moving the valve stem

through a 90" arc. Motor-controlled valves replace the handwheel with a fractional

horsepower motor that can be controlled remotely. The motor-operated valve operates

in exactly the same way as the manually operated valve.

Gate

Gate valves are used when straight-line, laminar fluid flow and minimum restrictions

are needed. These valves use a wedge-shaped sliding plate in the valve body to stop,

throttle, or permit full flow of fluids through the valve. When the valve is wide open,

the gate is completely inside the valve bonnet. This leaves the flow passage through

the valve fully open, with no flow restrictions, allowing little or no pressure drop

through the valve.

Gate valves are not suitable for throttling the flow volume unless specifically autho-

rized for this application by the manufacturer. They generally are not suitable because

the flow of fluid through a partially open gate can cause extensive damage to the

valve.

Gate valves are classified as either rising stem or non-rising stem. In the non-rising-

stem valve, shown in Figure 17-2, the stem is threaded into the gate. As the hand-

wheel on the stem is rotated, the gate travels up or down the stem on the threads,

while the stem remains vertically stationary. This type of valve almost always will

have a pointer indicator threaded onto the upper end of the stem to indicate the posi-

tion of the gate.