Page 171 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 171

Reverse Indicator Alignment

is placed on each machine. Figure 9-1 shows how the bar sag is

determined for reverse indicator method.

Once the bar sag values have been determined and recorded,

assure that both indicators are set to the plus bar sag when they

are in the 12 o’clock position. No further action is required to

compensate for bar sag.

The fixtures can now be reassembled to the machine, using

the reference marks as guides. An initial set of readings can now

be taken to assure the fixtures are properly assembled and suffi-

ciently ridged to return the indicators to their plus bar sag read-

ings at 12 o’clock, after being rotated 360 degrees.

MACHINE MEASUREMENTS

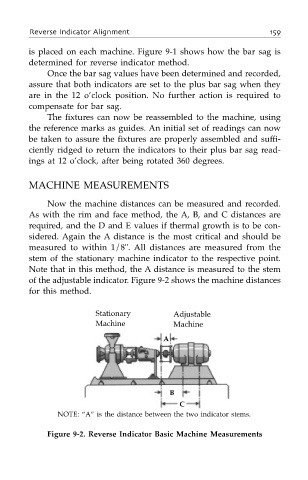

Now the machine distances can be measured and recorded.

As with the rim and face method, the A, B, and C distances are

required, and the D and E values if thermal growth is to be con-

sidered. Again the A distance is the most critical and should be

measured to within 1/8". All distances are measured from the

stem of the stationary machine indicator to the respective point.

Note that in this method, the A distance is measured to the stem

of the adjustable indicator. Figure 9-2 shows the machine distances

for this method.

Stationary Adjustable

Machine Machine

A

B

C

NOTE: “A” is the distance between the two indicator stems.

Figure 9-2. Reverse Indicator Basic Machine Measurements