Page 170 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 170

Rotating Machinery: Practical Solutions

Once the indicator fixtures are properly assembled on the

machine, and a trial set of readings taken to assure the fixture

clears the structure when rotated a full 360 degrees, its location on

the two shafts should be clearly marked. The fixtures are now

removed from the machine and placed on a ridged pipe or shaft

to determine bar sag. Note that in this method, both indicators

read a rim value, and thus both indicator fixtures must have their

bar sag accounted for.

BAR SAG

Once again, determining the bar sag is a straightforward

process. The indicators are set to zero in the 6 o’clock position and

rotated to the 12 o’clock position where the bar sag is read. Be sure

to determine the proper bar sag for each indicator fixture. Even

though the two fixtures are assembled the same, they may have

different amounts of sag.

It is doubly important to account for bar sag using this

method of alignment, since both indicator readings are affected.

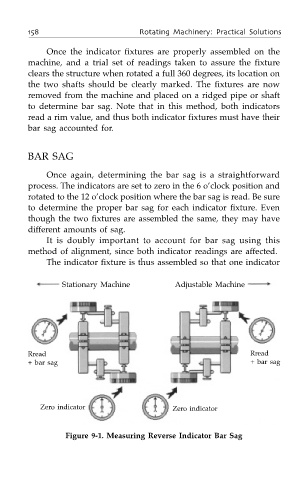

The indicator fixture is thus assembled so that one indicator

Stationary Machine Adjustable Machine

Rread Rread

+ bar sag + bar sag

Zero indicator Zero indicator

Figure 9-1. Measuring Reverse Indicator Bar Sag