Page 63 - Sensing, Intelligence, Motion : How Robots and Humans Move in an Unstructured World

P. 63

38 A QUICK SKETCH OF MAJOR ISSUES IN ROBOTICS

• Open-loop control, where the control action is applied regardless the system

errors

• Linear control, in which the control law is a linear relationship

• Nonlinear control, in which the control law is a nonlinear relationship

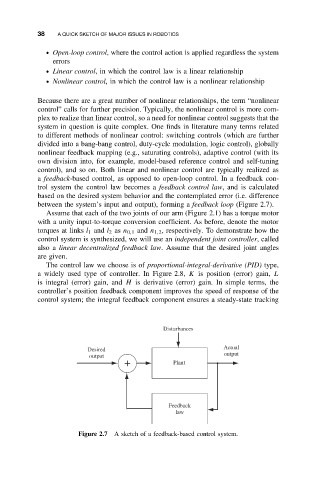

Because there are a great number of nonlinear relationships, the term “nonlinear

control” calls for further precision. Typically, the nonlinear control is more com-

plex to realize than linear control, so a need for nonlinear control suggests that the

system in question is quite complex. One finds in literature many terms related

to different methods of nonlinear control: switching controls (which are further

divided into a bang-bang control, duty-cycle modulation, logic control), globally

nonlinear feedback mapping (e.g., saturating controls), adaptive control (with its

own division into, for example, model-based reference control and self-tuning

control), and so on. Both linear and nonlinear control are typically realized as

a feedback-based control, as opposed to open-loop control. In a feedback con-

trol system the control law becomes a feedback control law, and is calculated

based on the desired system behavior and the contemplated error (i.e. difference

between the system’s input and output), forming a feedback loop (Figure 2.7).

Assume that each of the two joints of our arm (Figure 2.1) has a torque motor

with a unity input-to-torque conversion coefficient. As before, denote the motor

torques at links l 1 and l 2 as n 0,1 and n 1,2 , respectively. To demonstrate how the

control system is synthesized, we will use an independent joint controller, called

also a linear decentralized feedback law. Assume that the desired joint angles

are given.

The control law we choose is of proportional-integral-derivative (PID) type,

a widely used type of controller. In Figure 2.8, K is position (error) gain, L

is integral (error) gain, and H is derivative (error) gain. In simple terms, the

controller’s position feedback component improves the speed of response of the

control system; the integral feedback component ensures a steady-state tracking

Disturbances

Actual

Desired

output

output

Plant

Feedback

law

Figure 2.7 A sketch of a feedback-based control system.