Page 343 - Sensors and Control Systems in Manufacturing

P. 343

Advanced Sensors in Pr ecision Manufacturing

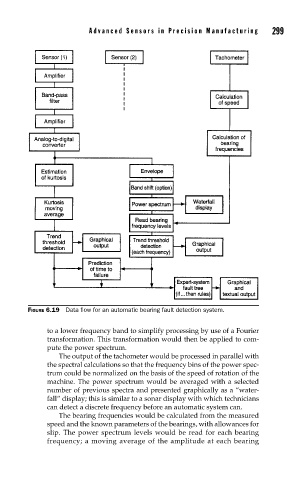

FIGURE 6.19 Data fl ow for an automatic bearing fault detection system. 299

to a lower frequency band to simplify processing by use of a Fourier

transformation. This transformation would then be applied to com-

pute the power spectrum.

The output of the tachometer would be processed in parallel with

the spectral calculations so that the frequency bins of the power spec-

trum could be normalized on the basis of the speed of rotation of the

machine. The power spectrum would be averaged with a selected

number of previous spectra and presented graphically as a “water-

fall” display; this is similar to a sonar display with which technicians

can detect a discrete frequency before an automatic system can.

The bearing frequencies would be calculated from the measured

speed and the known parameters of the bearings, with allowances for

slip. The power spectrum levels would be read for each bearing

frequency; a moving average of the amplitude at each bearing