Page 344 - Sensors and Control Systems in Manufacturing

P. 344

300

S i x

Cha p te r

frequency and harmonic would be maintained, and trends represent-

ing statistically significant increases would be identified by threshold

detection and indicated graphically.

By using algorithms based partly on analyses of data from prior

tests, the results of both keratosis and power spectrum calculations

would be processed onto predictions of the remaining operating time

until failure. All the results would then be processed by an expert

system. The final output would be a graphical display and text that

would describe the condition of the bearings.

6.18 Sensors for Vibration Measurement

of a Structure

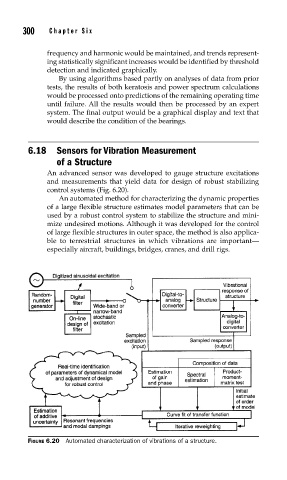

An advanced sensor was developed to gauge structure excitations

and measurements that yield data for design of robust stabilizing

control systems (Fig. 6.20).

An automated method for characterizing the dynamic properties

of a large flexible structure estimates model parameters that can be

used by a robust control system to stabilize the structure and mini-

mize undesired motions. Although it was developed for the control

of large flexible structures in outer space, the method is also applica-

ble to terrestrial structures in which vibrations are important—

especially aircraft, buildings, bridges, cranes, and drill rigs.

FIGURE 6.20 Automated characterization of vibrations of a structure.