Page 595 - Sensors and Control Systems in Manufacturing

P. 595

548

Cha p te r

Ele v e n

TOTAL COST

HOLDING COST

$ COST

EOQ

ORDERING COST

10 20 30 40 50 60 70 80 90 100

ORDER QUANTITY

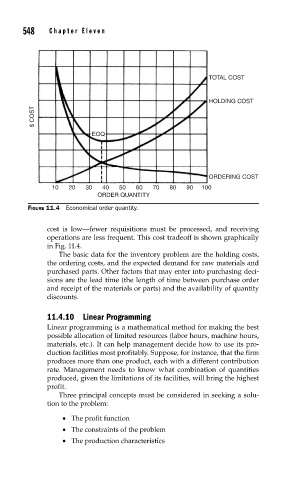

FIGURE 11.4 Economical order quantity.

cost is low—fewer requisitions must be processed, and receiving

operations are less frequent. This cost tradeoff is shown graphically

in Fig. 11.4.

The basic data for the inventory problem are the holding costs,

the ordering costs, and the expected demand for raw materials and

purchased parts. Other factors that may enter into purchasing deci-

sions are the lead time (the length of time between purchase order

and receipt of the materials or parts) and the availability of quantity

discounts.

11.4.10 Linear Programming

Linear programming is a mathematical method for making the best

possible allocation of limited resources (labor hours, machine hours,

materials, etc.). It can help management decide how to use its pro-

duction facilities most profitably. Suppose, for instance, that the firm

produces more than one product, each with a different contribution

rate. Management needs to know what combination of quantities

produced, given the limitations of its facilities, will bring the highest

profit.

Three principal concepts must be considered in seeking a solu-

tion to the problem:

• The profit function

• The constraints of the problem

• The production characteristics