Page 167 - Separation process engineering

P. 167

distillation column.

Example 4-4. McCabe-Thiele analysis of open steam heating

The feed is 60 mol% methanol and 40 mol% water and is input as a two-phase mixture that flashes so

that V /F = 0.3. Feed flow rate is 350 kmol/h. The column is well insulated and has a total condenser.

F

The reflux is returned to the column as a saturated liquid. An external reflux ratio of L /D = 3.0 is

0

used. We desire a distillate concentration of 95 mol% methanol and a bottoms concentration of 8

mol% methanol. Instead of using a reboiler, saturated steam at 1 atm is sparged directly into the

bottom of the column to provide boilup. (This is called direct or open steam.) Column pressure is 1

atm. Calculate the number of equilibrium stages and the optimum feed plate location.

Solution

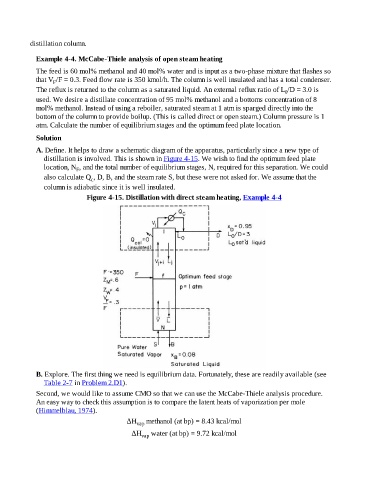

A. Define. It helps to draw a schematic diagram of the apparatus, particularly since a new type of

distillation is involved. This is shown in Figure 4-15. We wish to find the optimum feed plate

location, N , and the total number of equilibrium stages, N, required for this separation. We could

F

also calculate Q , D, B, and the steam rate S, but these were not asked for. We assume that the

c

column is adiabatic since it is well insulated.

Figure 4-15. Distillation with direct steam heating, Example 4-4

B. Explore. The first thing we need is equilibrium data. Fortunately, these are readily available (see

Table 2-7 in Problem 2.D1).

Second, we would like to assume CMO so that we can use the McCabe-Thiele analysis procedure.

An easy way to check this assumption is to compare the latent heats of vaporization per mole

(Himmelblau, 1974).

ΔH vap methanol (at bp) = 8.43 kcal/mol

ΔH vap water (at bp) = 9.72 kcal/mol