Page 223 - Separation process principles 2

P. 223

188 Chapter 5 Cascades and Hybrid Systems

-

Condenser

&=T+!I?

4 1

F Divider D

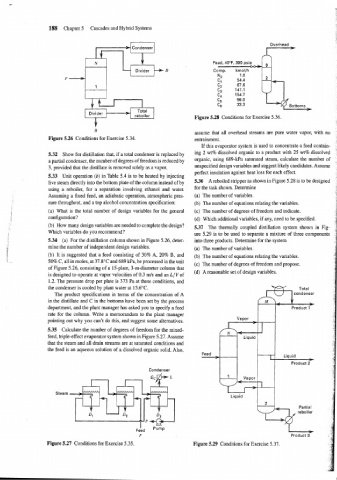

reboiler Figure 5.28 Conditions for Exercise 5.36.

I

1

B

assume that all overhead streams are pure water vapor, with no

Figure 5.26 Conditions for Exercise 5.34. entrainment. 1

If this evaporator system is used to concentrate a feed contain- 4

f '

5.32 Show for distillation that, if a total condenser is replaced by ing 2 wt% dissolved organic to a product with 25 wt% dissolved

organic, using 689-kPa saturated steam, calculate the number of 1

a partial condenser, the number of degrees of freedom is reduced by i

3, provided that the distillate is removed solely as a vapor. unspecified design variables and suggest likely candidates. Assume

perfect insulation against heat loss for each effect. I

5.33 Unit operation (b) in Table 5.4 is to be heated by injecting

live steam directly into the bottom plate of the column instead of by 5.36 Areboiled stripper as shown in Figure 5.28 is to be designed

using a reboiler, for a separation involving ethanol and water. for the task shown. Determine

Assuming a fixed feed, an adiabatic operation, atmospheric pres- (a) The number of variables.

sure throughout, and a top alcohol concentration specification: (b) The number of equations relating the variables.

(a) What is the total number of design variables for the general (c) The number of degrees of freedom and indicate.

configuration? (d) Which additional variables, if any, need to be specified.

(b) How many design variables are needed to complete the design?

5.37 The thermally coupled distillation system shown in Fig-

Which variables do you recommend?

ure 5.29 is to be used to separate a mixture of three components

5.34 (a) For the distillation column shown in Figure 5.26, deter- into three products. Determine for the system

mine the number of independent design variables. (a) The number of variables.

(b) It is suggested that a feed consisting of 30% A, 20% B, and (b) The number of equations relating the variables.

50% C, all in moles, at 373°C and 689 kPa, be processed in the unit

(c) The number of degrees of freedom and propose.

of Figure 5.26, consisting of a 15-plate, 3-m-diameter column that

(d) A reasonable set of design variables.

is designed to operate at vapor velocities of 0.3 mls and an L/V of

1.2. The pressure drop per plate is 373 Pa at these conditions, and

the condenser is cooled by plant water at 15.6OC. Total

The product specifications in terms of the concentration of A condenser

in the distillate and C in the bottoms have been set by the process

department, and the plant manager has asked you to specify a feed Product 1

rate for the column. Write a memorandum to the plant manager

Vapor

pointing out why you can't do this, and suggest some alternatives.

5.35 Calculate the number of degrees of freedom for the mixed-

feed, triple-effect evaporator system shown in Figure 5.27. Assume Liquid

that the steam and all drain streams are at saturated conditions and

the feed is an aqueous solution of a dissolved organic solid. Also,

Feed - I Liquid -

Product 2 fl

Condenser

Vapor

1

Steam

Liquid

Partial

reboiler

Product <

Figure 5.27 Conditions for Exercise 5.35. Figure 5.29 Conditions for Exercise 5.37.