Page 224 - Separation process principles 2

P. 224

Exercises 189

Essentially

impurities

1 atm pressure

throughout

system

Pasteurizing{

section

Distillate

Steam -

k- Bottoms

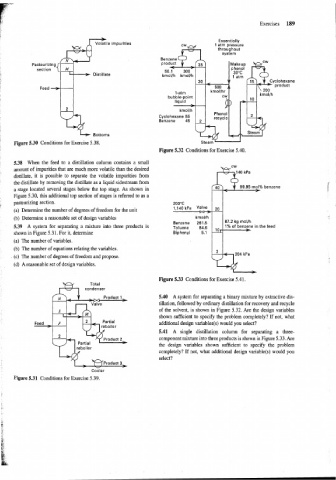

Figure 5.30 Conditions for Exercise 5.38.

Figure 5.32 Conditions for Exercise 5.40.

5.38 When the feed to a distillation column contains a small

amount of impurities that are much more volatile than the desired

distillate, it is possible to separate the volatile impurities from +

the distillate by removing the distillate as a liquid sidestream from

a stage located several stages below the top stage. As shown in 99.95 mot% benzene

Figure 5.30, this additional top section of stages is referred to as a

pasteurizing section.

(a) Determine the number of degrees of freedom for the unit

(b) Determine a reasonable set of design variables kmollh

Benzene 261.5 87.2 kg mollh

5.39 A system for separating a mixture into three products is Toluene 1% of benzene in the feed

shown in Figure 5.31. For it, determine Biphenyl 5.1

(a) The number of variables.

(b) The number of equations relating the variables.

(c) The number of degrees of freedom and propose.

(d) A reasonable set of design variables.

Figure 5.33 Conditions for Exercise 5.41.

Total

condenser

Product 1 5.40 A system for separating a binary mixture by extractive dis-

tillation, followed by ordinary distillation for recovery and recycle

of the solvent, is shown in Figure 5.32. Are the design variables

shown sufficient to specify the problem completely? If not, what

2 , Partial

F

Feed , additional design variables(s) would you select?

c

5.41 A single distillation column for separating a three-

component mixture into three products is shown in Figure 5.33. Are

the design variables shown sufficient to specify the problem

completely? If not, what additional design variable(s) would you

h

select?

Product 3

Cooler

Figure 5.31 Conditions for Exercise 5.39.