Page 138 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 138

CH11pp111-125 4/10/02 12:51 PM Page 116

116 Serious Incident Prevention

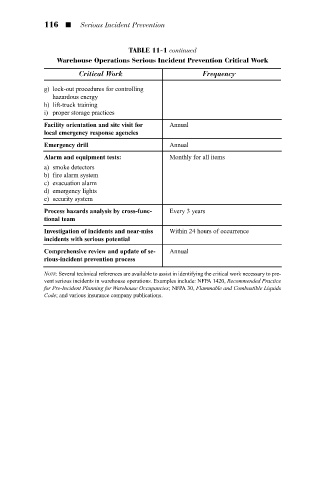

TABLE 11-1 continued

Warehouse Operations Serious Incident Prevention Critical Work

Critical Work Frequency

g) lock-out procedures for controlling

hazardous energy

h) lift-truck training

i) proper storage practices

Facility orientation and site visit for Annual

local emergency response agencies

Emergency drill Annual

Alarm and equipment tests: Monthly for all items

a) smoke detectors

b) fire alarm system

c) evacuation alarm

d) emergency lights

e) security system

Process hazards analysis by cross-func- Every 3 years

tional team

Investigation of incidents and near-miss Within 24 hours of occurrence

incidents with serious potential

Comprehensive review and update of se- Annual

rious-incident prevention process

NOTE: Several technical references are available to assist in identifying the critical work necessary to pre-

vent serious incidents in warehouse operations. Examples include: NFPA 1420, Recommended Practice

for Pre-Incident Planning for Warehouse Occupancies; NFPA 30, Flammable and Combustible Liquids

Code; and various insurance company publications.